Top 10 Benefits of Using Digital Garment Printing Machines for Your Business

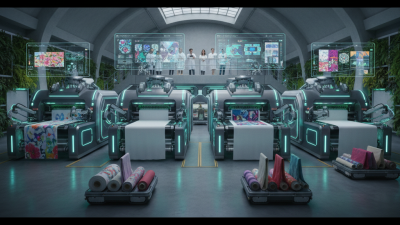

In the rapidly evolving landscape of fashion and textile production, businesses are constantly seeking innovative solutions to enhance efficiency and creativity. Among the most transformative technologies available today is the digital garment printing machine, a tool that has revolutionized the way garments are designed and produced. This advanced printing approach not only streamlines the manufacturing process but also offers unparalleled customization options, allowing businesses to meet diverse consumer demands with ease.

The advantages of integrating a digital garment printing machine into your operations are manifold. From reducing waste and minimizing setup times to enabling vibrant and intricate designs, these machines cater to both small-scale enterprises and large manufacturers alike. As we delve into the top ten benefits of utilizing digital garment printing machines, it becomes evident that they provide a significant competitive edge in a market that increasingly values personalization and sustainability. Embracing this technology can position businesses at the forefront of innovation, ultimately leading to enhanced customer satisfaction and increased profitability.

Advantages of Digital Garment Printing Machines in Modern Apparel Business

The digital garment printing industry has witnessed significant growth in recent years, revolutionizing the way apparel businesses operate. According to a report by MarketsandMarkets, the digital textile printing market size is projected to reach $4.9 billion by 2025, growing at a CAGR of 17.3%. This growth is driven by the increasing demand for customized and short-run fabric printing, which digital printing machines cater to exceptionally well.

One of the key advantages of digital garment printing machines is their ability to produce intricate designs without the need for expensive screens and setup costs. This enables businesses to create unique designs on demand, thus reducing inventory costs and minimizing waste. The flexibility of digital printing allows companies to quickly adapt to fashion trends and customer preferences, providing a competitive edge in the fast-paced apparel market.

Tip: To maximize the benefits of digital printing, consider investing in a high-resolution printer that supports a wide variety of fabrics, which will enhance the quality of your garments and expand your product offerings.

Moreover, digital garment printing supports sustainable practices by using less water and generating less pollution compared to traditional printing methods. A study by the Environmental Protection Agency (EPA) indicates that digital printing can reduce water usage by up to 50% and minimize energy consumption, contributing to a greener apparel industry.

Tip: Implement eco-friendly inks and materials in your digital printing process to attract environmentally conscious consumers and promote sustainability within your brand.

Cost Efficiency: Reducing Production Expenses with Digital Printing

Digital garment printing machines offer significant cost efficiency that can profoundly benefit businesses in the apparel industry. One of the primary advantages of adopting this technology is the reduction of production expenses. Traditional printing methods often involve lengthy setup times, extensive material waste, and labor-intensive processes, all of which contribute to higher operating costs. In contrast, digital printing allows for faster turnaround times and minimizes excess material usage by printing only what is necessary, ensuring that businesses can meet customer demands without incurring unnecessary waste.

Moreover, the flexibility of digital printing enables businesses to produce smaller batches without incurring hefty fees associated with large print runs. This feature is particularly advantageous for companies that want to test new designs or cater to niche markets. With digital printing, there is no need to invest in extensive inventory since products can be printed on demand. This not only conserves valuable resources but also enhances cash flow by reducing the risk of overproduction and unsold inventory. By leveraging digital garment printing, businesses can streamline their operations, making them more agile and responsive to market trends while keeping costs manageable.

| Benefit | Description | Cost Savings | Production Time |

|---|---|---|---|

| Lower Setup Costs | Digital printing eliminates the need for screens and setups. | 30% | 5-10 hours |

| Reduced Material Waste | Only prints necessary colors, minimizing leftover materials. | 20% | 4-8 hours |

| Quick Turnaround | Faster printing processes for timely delivery. | 25% | 1-3 days |

| No Minimum Order Quantities | Ideal for small businesses and custom orders. | 35% | 2-6 hours |

| Flexibility in Design | Easily adjust designs without extra cost. | 15% | 2-4 hours |

| High-Quality Prints | Sharp and vibrant prints with fine detail. | 10% | 1-2 days |

| Easier Color Management | Automatic color matching reduces inconsistencies. | 15% | 1-3 days |

| Eco-Friendly Options | Uses less water and non-toxic inks. | Reduction in 20% energy costs | 2-4 days |

| Enhanced Customer Satisfaction | Faster responses to customer requests and personalized designs. | Estimated increase of 30% in repeat customers | 1-3 days |

Customization Capabilities: Offering Personalized Designs for Customers

Digital garment printing machines have revolutionized the custom apparel market, allowing businesses to tap into the growing demand for personalized designs among consumers. According to a report by Smithers Pira, the global digital textile printing market is projected to reach $3.5 billion by 2024, reflecting a compound annual growth rate (CAGR) of 20%. This surge indicates a clear trend towards customization, where customers are increasingly looking for unique, tailored options that reflect their personal style, preferences, or brand identity.

One of the standout advantages of utilizing digital garment printing is the ability to offer highly individualized designs without the limitations of traditional printing methods. With digital printing, businesses can easily produce short runs of various designs, catering to specific customer requests or seasonal trends. The technology allows for intricate artwork and vibrant colors that can be altered quickly, ensuring rapid response times to market demands. Furthermore, a survey by the Custom Apparel Association reveals that 70% of consumers prefer brands that offer customization options, showcasing a significant opportunity for businesses to enhance customer satisfaction and loyalty through personalized products. This capability not only meets immediate consumer desires but also positions companies competitively in an increasingly crowded marketplace.

Speed and Efficiency: Enhancing Production Turnaround Times

Digital garment printing machines are revolutionizing the way businesses approach production by significantly enhancing speed and efficiency. Traditional printing methods often involve lengthy setup times and labor-intensive processes, which can delay project completion. In contrast, digital printing allows for quicker turnaround, enabling businesses to respond swiftly to market demands. With the ability to print designs directly from a digital file, companies can produce high-quality customized garments in a fraction of the time, thus boosting their overall productivity.

Tips for maximizing the efficiency of your digital printing process include streamlining your design workflow. Implementing software that integrates design and printing stages can save valuable time. Additionally, maintaining your equipment regularly ensures optimal performance, reducing downtime and preventing production bottlenecks. Finally, consider using automated systems for order management and inventory tracking to keep everything organized and running smoothly, which allows your team to focus more on creative aspects rather than administrative tasks.

By investing in digital garment printing technology, businesses can not only enhance their production capabilities but also improve their service levels. Faster turnaround times mean quicker delivery to clients, enabling you to build stronger relationships and trust within the market. This agility ultimately positions your business as a leader in an increasingly competitive landscape, ready to meet the demands of modern consumers.

Environmental Impact: Sustainable Printing Practices with Digital Technology

Digital garment printing machines represent a significant advancement in the textile industry, particularly when it comes to sustainable printing practices. Unlike traditional printing methods, digital printing minimizes waste by using only the necessary amount of ink and materials. This helps reduce the environmental impact associated with excess production, making it a more eco-friendly choice for businesses. Additionally, digital printing technologies often utilize water-based inks that are less harmful to the environment, further contributing to the sustainability of the process.

Tips: To optimize for sustainability, ensure that the digital printing machines you choose are designed for efficiency, ideally with quick changeovers and minimal setup waste. Focus on sourcing materials from suppliers who prioritize recycled or organic fabrics, allowing your business to further enhance its environmentally friendly practices.

Furthermore, the versatility of digital garment printing allows for on-demand production, which significantly reduces overstock and waste. By producing items only when there is a confirmed demand, businesses can not only save money but also limit the environmental strain from unsold inventory. Educating customers about the benefits of on-demand fashion can also promote a more sustainable buying behavior, encouraging them to think critically about their consumption habits.

Tips: Implement a clear communication strategy emphasizing your commitment to sustainable practices. Consider offering limited editions or customizable options that allow customers to participate in the sustainable model of production while directly influencing the items being printed.

Conclusion

Digital garment printing machines have revolutionized the apparel industry by offering numerous advantages that enhance business operations. One significant benefit is cost efficiency; these machines help reduce production expenses by minimizing waste and lowering setup costs compared to traditional printing methods. Additionally, the customization capabilities of digital garment printing allow businesses to provide personalized designs, catering to individual customer preferences and improving customer satisfaction.

Moreover, digital garment printing machines enhance production speed and efficiency, leading to quicker turnaround times. This is crucial in today’s fast-paced fashion market, where trends change rapidly. The environmental impact of using these machines is also noteworthy, as they promote sustainable printing practices that reduce harmful waste. Lastly, they ensure quality consistency, achieving superior print quality across batches, which is essential for maintaining brand reputation in a competitive landscape. Overall, incorporating digital garment printing machines into a business strategy can lead to significant operational improvements.

Related Posts

-

How to Effectively Use Textile Waste Recycling Machine for Sustainable Practices

-

2025 How to Choose the Best Weaving Machine for Your Business Needs

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production

-

What is a Fabric Recycling Machine and How Does It Benefit the Environment

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production

-

Why Choosing the Right Fabric Making Machine is Essential for Your Business Success