Top Benefits of Using Fabric Inspection Machines for Quality Control

The textile industry is increasingly recognizing the vital role that fabric inspection machines play in maintaining quality control throughout the production process. According to a report by the Textile Quality Association, up to 30% of production costs can be attributed to defects in fabric, making effective inspection crucial for manufacturers aiming to optimize their operations and enhance product quality. In an era where consumer demands for impeccable quality are at an all-time high, integrating advanced fabric inspection technology is not merely advantageous but essential.

Industry expert Dr. Emily Carter emphasizes the importance of these machines, stating, “Investing in a fabric inspection machine not only mitigates the risk of defects but also significantly improves overall production efficiency.” As manufacturers adopt fabric inspection machines, they not only protect their bottom line but also enhance their reputation in a competitive market. The growing adoption of automation in the textile sector underscores a trend towards greater precision and reliability in quality control processes, underlining the importance of having robust inspection solutions in place to safeguard against imperfections.

Understanding Fabric Inspection Machines and Their Role in Quality Control

Fabric inspection machines play a crucial role in quality control within the textile industry. These machines are designed to thoroughly examine fabrics for defects, ensuring that the final product meets the required standards before reaching consumers. By automating the inspection process, these machines increase efficiency, reduce human error, and provide consistent results. Understanding how these machines operate helps manufacturers implement effective quality control measures, leading to improved fabric quality and customer satisfaction.

When considering the integration of fabric inspection machines, it’s essential to select models that align with your specific needs. Tips for choosing the right fabric inspection machine include assessing the types of fabrics you will inspect, evaluating the machine’s features such as speed and detection accuracy, and considering the ease of use for operators. Regular maintenance is also key to ensuring these machines operate at optimal levels and prolong their lifespan.

Moreover, training staff to utilize these machines effectively can significantly impact the overall quality control process. Tips for effective training programs include hands-on demonstrations, providing easy-to-understand manuals, and creating a feedback mechanism for continuous improvement. By investing time in training, manufacturers can maximize the benefits of fabric inspection machines, enhancing production quality and operational efficiency.

Key Advantages of Fabric Inspection Machines in the Textile Industry

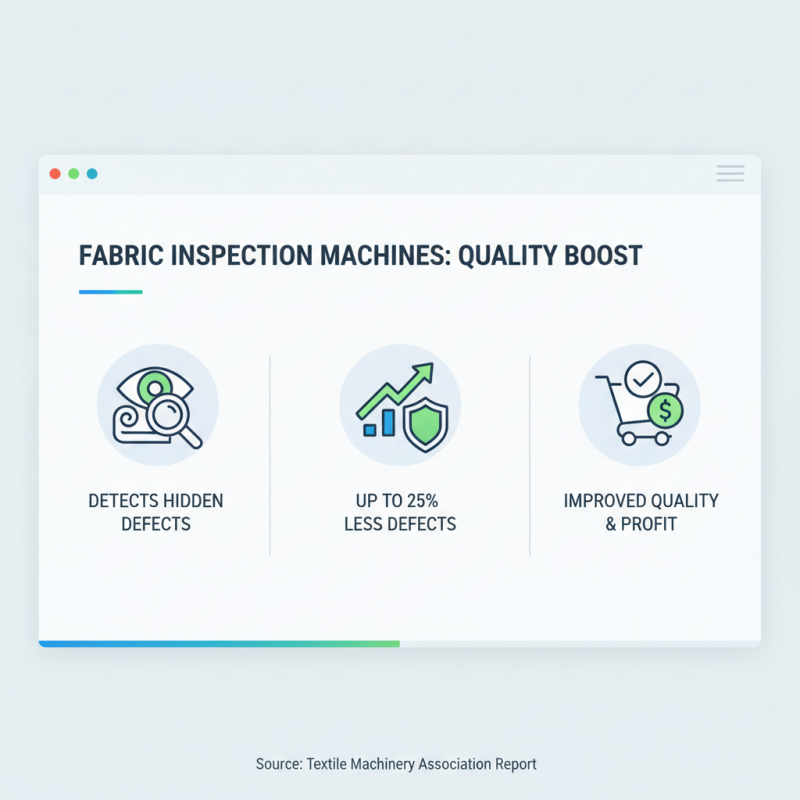

Fabric inspection machines play a critical role in the textile industry, offering several key advantages that enhance quality control processes. One major benefit is their ability to accurately detect defects in fabric that may not be visible to the human eye. According to a report by the Textile Machinery Association, using automated inspection systems can reduce fabric defects by up to 25%, thereby significantly improving product quality. This reduction in defects not only enhances customer satisfaction but also minimizes costly returns and rework, which can severely impact profit margins.

Moreover, fabric inspection machines can operate at high speeds, allowing for thorough inspections without disrupting production flow. The International Textile Manufacturers Federation states that automated inspection can increase inspection efficiency by 40%, enabling manufacturers to process larger volumes of fabric in a shorter time frame. This increase in productivity is essential as the textile market continues to evolve with rising demand from consumers for high-quality products delivered in a timely manner. By integrating advanced technology into their quality control processes, textile manufacturers can stay competitive in a rapidly changing industry landscape, ensuring that they meet both quality standards and consumer expectations.

Statistical Impact of Automated Inspections on Defect Detection Rates

The implementation of automated fabric inspection machines has significantly transformed quality control processes in the textile industry, particularly in enhancing defect detection rates. Traditionally, manual inspection methods were reliant on the expertise and attention of workers, which often led to inconsistencies and overlooked defects. However, automated systems utilize advanced algorithms and imaging technologies to meticulously analyze fabric surfaces, offering a level of precision that is difficult to achieve manually. As a result, the statistical impact of these machines on defect detection rates has been profound, with numerous studies demonstrating marked improvements in identifying flaws that might otherwise go unnoticed.

Quantitative analyses reveal that automated inspections can increase defect detection rates by significant margins compared to traditional methods. In several cases, facilities implementing these machines have reported up to a 50% reduction in defects reaching the final product stage. This increase not only boosts product quality but also enhances overall operational efficiency, reducing waste and the cost associated with reworking or returning defective items. Furthermore, consistent data gathered from automated inspections facilitates better decision-making and trend analysis, allowing manufacturers to continually refine their processes and uphold high standards in quality control.

Top Benefits of Using Fabric Inspection Machines for Quality Control

| Inspection Method | Defect Detection Rate (%) | Time Taken (Minutes) | Cost Per Inspection ($) | Error Rate (%) |

|---|---|---|---|---|

| Manual Inspection | 75 | 30 | 20 | 10 |

| Semi-Automated Inspection | 85 | 20 | 30 | 5 |

| Fully Automated Inspection | 95 | 10 | 50 | 2 |

Cost-Benefit Analysis of Implementing Fabric Inspection Technologies

Implementing fabric inspection technologies is a strategic move that can significantly enhance a company's quality control process while providing a favorable cost-benefit ratio. The initial investment in advanced inspection machines may seem substantial, but the long-term savings and efficiency gains they bring often outweigh the upfront costs. By automating the inspection process, companies can drastically reduce labor costs associated with manual inspections and minimize human errors that can lead to defective products. This efficiency not only streamlines operations but also accelerates production timelines, allowing manufacturers to meet market demands more swiftly.

Moreover, the adoption of fabric inspection technologies contributes to higher product quality, which is crucial for maintaining customer satisfaction and loyalty. Enhanced quality control measures can lead to a reduction in returns and complaints, saving the company from potential financial losses associated with unsold inventory and reputation damage. Over time, the reputation for superior quality can serve as a competitive advantage in the marketplace, ultimately driving sales and profitability. Thus, while the initial cost may pose a challenge for some, the investment in fabric inspection technologies proves to be a crucial element in achieving sustainable growth and operational excellence.

Future Trends in Fabric Inspection Technology and Quality Assurance Practices

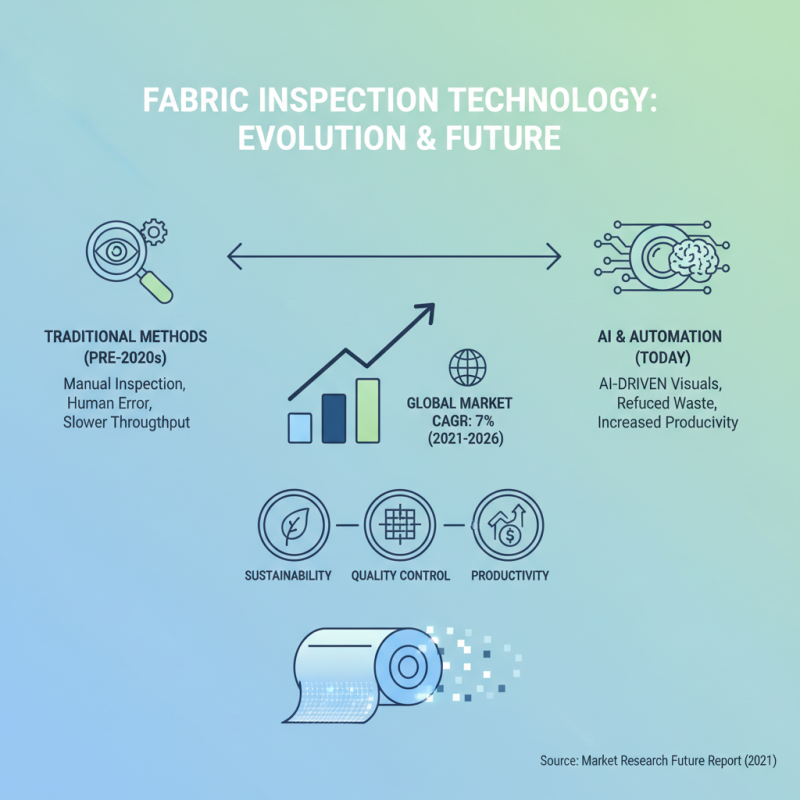

The landscape of fabric inspection technology is continuously evolving, driven by advancements in automation and data analytics. According to a recent report by Market Research Future, the global fabric inspection machine market is projected to grow at a CAGR of 7% between 2021 and 2026. This growth reflects increasing demand for precise quality control in the textile industry, where the emphasis on sustainability and defect reduction is paramount. As manufacturers integrate AI-driven visual inspection systems, they can detect fabric flaws with remarkable accuracy, reducing human error and increasing overall productivity.

Furthermore, the use of machine learning algorithms in fabric inspection is set to revolutionize quality assurance practices. A study from the International Journal of Textile Science revealed that automating quality checks can reduce inspection times by up to 50%, allowing companies to focus on enhancing their production efficiency. By implementing predictive analytics, fabric inspection machines can not only identify current defects but also predict potential quality issues before they arise, enabling proactive measures to maintain fabric integrity. As the industry moves towards more sophisticated technologies, the adoption of such intelligent solutions will be crucial in achieving higher standards of quality and sustainability.

Related Posts

-

Why Investing in Textile Machinery is Essential for Modern Manufacturing Success

-

Top 5 Benefits of Using Industrial Fabric Laser Cutting Machines for Your Business

-

How to Choose the Best Fabric Laser Cutting Machine in 2025

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production

-

What is a Fabric Weaving Machine and How Does it Work in Textile Production

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production