Top 10 Best Weaving Machines for Efficient Textile Production

The textile industry has always been at the forefront of innovation, and at its heart lies the weaving machine—an essential tool that transforms raw fibers into intricate fabrics. As demands for efficiency and quality continue to rise, the importance of selecting the right weaving machine cannot be overstated. This article delves into the top 10 best weaving machines available today, highlighting their features, capabilities, and the roles they play in enhancing productivity within textile production.

Modern weaving machines have evolved significantly, integrating advanced technologies that allow for faster operation, precision, and versatility in fabric creation. From automated systems that reduce labor costs to machines capable of producing complex patterns, the landscape of weaving technology is rich and varied. By understanding the options available, businesses can make informed decisions that align with their production needs and sustainability goals, paving the way for a more efficient and competitive textile industry.

In this comprehensive overview, we will explore the key factors to consider when choosing a weaving machine, including speed, ease of use, maintenance requirements, and the types of fabrics they can produce. Whether you are a large-scale manufacturer or a small artisan business, this guide aims to equip you with the knowledge necessary to enhance your textile production process.

Top Ten Weaving Machines: A Comprehensive Overview for Textile Efficiency

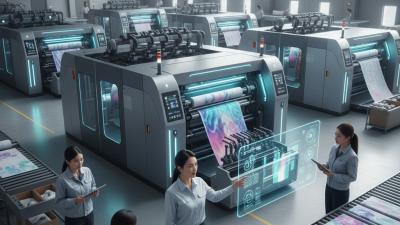

When considering the efficiency of textile production, the choice of weaving machine plays a pivotal role. These machines not only streamline the weaving process but also enhance the quality and consistency of produced textiles. A comprehensive overview of the top ten weaving machines reveals a variety of features designed to meet the diverse needs of modern textile manufacturing. For instance, advancements in technology such as automated systems and digital interfaces have drastically improved production rates and reduced labor intensity.

Moreover, efficiency in textile production is closely linked to the machine's versatility and adaptability to different fabric types. Machines that support a wide range of yarns and patterns allow manufacturers to be more responsive to market demands, minimizing downtime and maximizing output. Additionally, energy efficiency has become a significant consideration, as sustainable production methods are increasingly prioritized in the industry. By focusing on these aspects, businesses can select weaving machines that not only increase productivity but also align with ecological goals, ultimately fostering a more efficient and responsible textile production environment.

Key Features to Consider When Selecting Weaving Machines for Production

When selecting weaving machines for efficient textile production, several key features should be considered to ensure optimal performance and productivity. Firstly, the machine's speed is crucial; a higher speed allows for increased output, significantly enhancing production efficiency. Additionally, the machine's versatility in handling different fabric types and patterns can greatly expand a textile producer's capabilities, making it easier to meet diverse market demands.

Another important aspect to consider is the automation level of the weaving machine. Advanced automation features, such as automatic shuttle changing and integrated control systems, can reduce manual intervention and minimize errors, leading to a smoother production process. Furthermore, easy maintenance and repair options are essential for minimizing downtime and keeping production running smoothly. A well-designed machine that allows for quick maintenance will support continuous operation, ultimately contributing to a more efficient weaving process.

Comparison of Weaving Machine Technologies: Rapier, Jacquard, and Air Jet

When exploring the various types of weaving machines, it's essential to understand the distinct technologies at play—particularly rapier, Jacquard, and air jet weaving machines. Rapier weaving machines utilize a shuttleless mechanism where a rapier inserts the weft yarn by dragging it across the width of the loom. This method is valued for its versatility, allowing for a wide range of fabrics and patterns to be produced efficiently.

Jacquard machines, on the other hand, are celebrated for their capability to weave intricate designs and patterns. Utilizing a series of punch cards or digital controls, Jacquard machines can create complex textiles with ease, making them ideal for high-end fashion and unique designs. For textile producers looking to add a creative touch to their products, investing in Jacquard technology could enhance their offerings considerably.

Air jet weaving machines represent a newer innovation, where high-pressure air is used to propel the weft yarn across the loom. This technology boasts high-speed production rates and reduced noise levels, making it a great option for large-scale textile manufacturing. Tips for maximizing efficiency with these machines include regular maintenance to ensure optimal performance and investing in staff training to fully leverage the capabilities of each technology. By considering these weaving machine technologies, textile producers can align their production processes with their specific needs and market demands.

Top 10 Best Weaving Machines for Efficient Textile Production

| Machine Type | Max Width (cm) | Production Speed (m/min) | Technology | Suitable Fabrics |

|---|---|---|---|---|

| Rapier Weaving Machine | 340 | 800 | Rapier | Cotton, Wool |

| Jacquard Weaving Machine | 240 | 600 | Jacquard | Silk, Taffeta |

| Air Jet Weaving Machine | 300 | 1000 | Air Jet | Synthetic, Denim |

| Projectile Weaving Machine | 280 | 400 | Projectile | Heavy Fabrics |

| Shuttle Weaving Machine | 320 | 500 | Shuttle | Cotton, Mixed Fibers |

| Tape Loom | 200 | 350 | Tape | Narrow Fabrics |

| Leno Weaving Machine | 270 | 450 | Leno | Lightweight Fabrics |

| Multi-Shuttle Machine | 310 | 850 | Multi-Shuttle | Wool, Blends |

| Cylinder Loom | 360 | 400 | Cylinder | Technical Textiles |

| Water Jet Loom | 330 | 900 | Water Jet | Synthetic, Nylon |

Industry Applications: How Weaving Machines Impact Textile Production

Weaving machines play a crucial role in the textile industry, significantly impacting production efficiency and the overall quality of fabrics. By automating the weaving process, these machines enhance productivity, allowing manufacturers to meet growing market demands without sacrificing quality. Their precision helps in achieving uniformity in fabric structure, which is essential for ensuring that the final products maintain consistency in strength and durability. Additionally, advanced technologies integrated into modern weaving machines, such as computerized controls and electronic sensors, allow for real-time adjustments, further improving the efficiency of textile production.

In various industry applications, weaving machines are adapted to cater to specific fabric requirements, ranging from lightweight materials for clothing to heavier, more robust textiles used in upholstery and industrial applications. The ability to produce different types of weaves, including plain, twill, and satin, allows manufacturers to diversify their offerings and respond quickly to changing consumer preferences. Moreover, the scalability of these machines enables businesses to start small and expand production capacity as demand increases, making weaving machines an indispensable asset in the competitive textile market. With ongoing innovations, the impact of weaving machines on textile production is set to grow, driving advancements in efficiency, sustainability, and creativity within the industry.

Cost-Benefit Analysis of Investing in Advanced Weaving Technologies

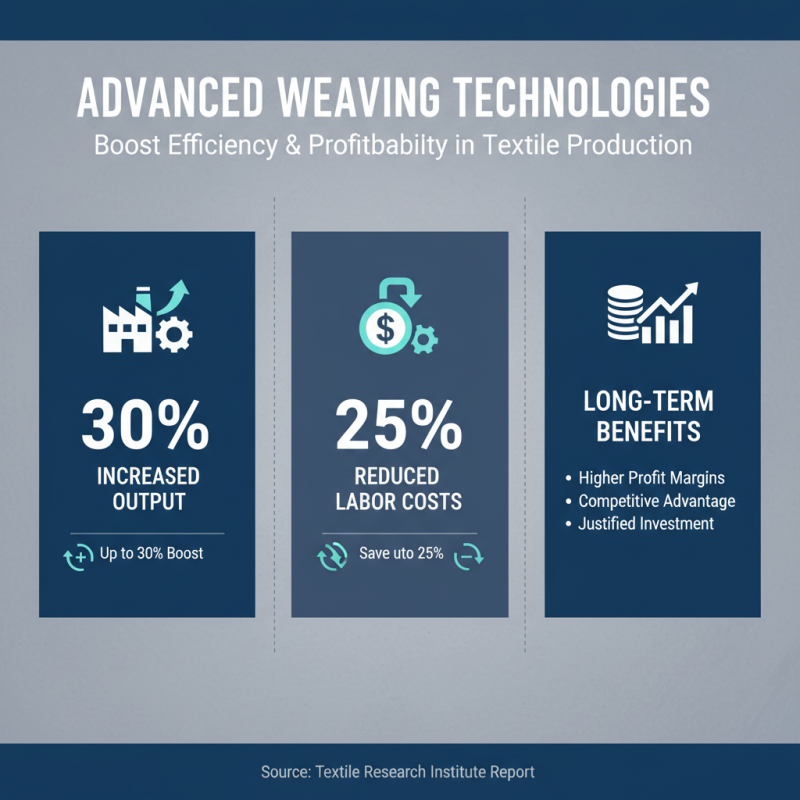

Investing in advanced weaving technologies can significantly impact the efficiency and profitability of textile production. According to a recent report by the Textile Research Institute, companies that adopt modern weaving machines can boost their output by up to 30% while reducing labor costs by as much as 25%. This cost-benefit ratio is crucial in a competitive market where profit margins are continually pressured. The initial capital outlay may be substantial, but the long-term savings and increased production capacity often justify the investment.

Moreover, advanced weaving machines offer enhanced precision and reduced material waste, which aligns with sustainable production practices. The International Textile Manufacturers Federation highlights that improved machine capabilities can lower fabric defects by nearly 40%, leading to less rework and downgrading costs. Furthermore, with the industry increasingly leaning toward eco-friendly production, these machines are often designed to minimize energy consumption, thus cutting operational costs. This dual advantage of financial savings and environmental responsibility makes investing in advanced weaving technologies an attractive proposition for textile manufacturers aiming for resilience in an evolving market landscape.

Related Posts

-

How to Effectively Use Textile Waste Recycling Machine for Sustainable Practices

-

What is a Fabric Weaving Machine and How Does it Work in Textile Production

-

2025 Top 10 Textile Printing Machines Revolutionizing the Industry

-

What is a Fabric Recycling Machine and How Does It Benefit the Environment

-

Revolutionize Your Business with Advanced Industrial Fabric Printing Machines: Trends and Tips for Success

-

How to Choose the Best Fabric Laser Cutting Machine in 2025