Top 10 Best Wet Spinning Machines for Efficient Fiber Production in 2023

The textile industry continues to evolve with advancements in technology, particularly in the production of synthetic fibers. Among the crucial equipment in this domain, the wet spinning machine stands out as a key player in enhancing efficiency and quality. According to a report by MarketsandMarkets, the global wet spinning market is projected to grow significantly, driven by the increasing demand for high-performance fibers in diverse applications, including automotive and aerospace sectors. This growth underscores the importance of selecting the right wet spinning machine, which can directly impact the fiber production speed, cost, and sustainability.

In 2023, manufacturers are looking for wet spinning machines that incorporate the latest innovations, such as automation and energy-efficient technologies, to meet the rising demand for high-quality fibers. The improvement in these machines not only increases throughput but also minimizes environmental impact, aligning with the global push towards sustainability in manufacturing processes. Understanding the various options available in the market is critical for companies aiming to optimize their production lines and maintain competitive advantage.

This guide presents the top 10 best wet spinning machines of 2023, focusing on their features, efficiencies, and how they can meet the evolving needs of fiber producers. By leveraging these advanced technologies, businesses can enhance their production capabilities while adhering to industry standards and sustainability goals.

Overview of Wet Spinning Technology in Fiber Production

Wet spinning technology is a pivotal process in the fiber production industry, particularly known for its ability to create high-quality synthetic fibers such as viscose and acrylic. This method involves dissolving raw materials in a solvent to form a viscous solution, which is then extruded through spinnerets into a coagulating bath. This process not only allows for the production of fibers with exceptional mechanical properties but also enhances dye uptake, resulting in vibrant colors that are more resistant to fading. According to industry reports, the wet spinning segment is projected to experience a compound annual growth rate (CAGR) of approximately 5% from 2022 to 2028, reflecting its strong demand in the textile market.

When selecting a wet spinning machine, it is crucial to consider factors such as the yarn denier, spinning speed, and the efficiency of the coagulation process. Opting for machines that offer precise control over these parameters can lead to significant improvements in fiber quality and production efficiency. For instance, research has shown that optimizing the temperature and concentration of the coagulation bath can enhance filament uniformity and reduce defects, which can otherwise impact the final product's performance.

Tips: Ensure regular maintenance of spinning machines to avoid downtime and maximize output. Monitoring the viscosity of the spinning solution is key; maintaining optimal viscosity not only ensures consistency in fiber quality but also prevents machine wear and tear, enhancing longevity. Furthermore, investing in modern control systems can facilitate real-time monitoring and adjustments, thereby boosting operational efficiency and fiber quality.

Key Factors to Consider When Choosing a Wet Spinning Machine

When selecting a wet spinning machine for fiber production, several key factors must be taken into account to ensure optimal performance and efficiency. First and foremost, the machine's capacity should align with your production needs. Assessing the throughput capabilities—a balance between speed and quality—is essential to prevent bottlenecks and ensure consistency in output.

Another crucial consideration is the technology used in the machine. Look for features that enhance the spinning process, such as automatic tension control and precise temperature regulation. These advancements can significantly improve fiber quality and reduce energy consumption. Additionally, ease of operation and maintenance is paramount; machines that incorporate user-friendly interfaces or require less downtime for servicing can lead to enhanced productivity overall.

Tips: Always evaluate the scalability of the wet spinning machine. Consider if it can adapt to an increase in production demands or if modifications can be easily implemented to accommodate new types of fibers. Furthermore, consult with current users or industry experts to gather insights on the machine’s real-world performance and reliability, as firsthand experiences can highlight potential advantages or shortcomings that specifications alone may not reveal.

Top 10 Best Wet Spinning Machines for Efficient Fiber Production in 2023

| Machine Model | Production Capacity (kg/h) | Energy Consumption (kWh) | Control Type | Key Feature |

|---|---|---|---|---|

| Model A | 300 | 50 | Automatic | High efficiency |

| Model B | 250 | 45 | Semi-Automatic | Compact design |

| Model C | 350 | 55 | Fully Automatic | High yield |

| Model D | 400 | 60 | Automatic | Durable build |

| Model E | 280 | 48 | Manual | Cost-effective |

| Model F | 320 | 52 | Semi-Automatic | User-friendly |

| Model G | 360 | 58 | Fully Automatic | Innovative technology |

| Model H | 450 | 62 | Automatic | High performance |

| Model I | 290 | 49 | Manual | Easy maintenance |

| Model J | 330 | 54 | Semi-Automatic | Versatile application |

Top 10 Wet Spinning Machines of 2023: Features and Specifications

In the realm of fiber production, the advancements in wet spinning machines have significantly enhanced

efficiency and output quality. The top machines of 2023 offer a variety of features designed to meet the diverse needs of manufacturers.

Modern wet spinning machines come equipped with precise temperature controls, ensuring optimal conditions for fiber formation.

Additionally, many models incorporate automated systems for monitoring viscosity and flow rates, leading to consistent production rates

and reduced material waste.

Another crucial aspect of these machines is their adaptability to various fiber types, including synthetic and natural fibers.

The best wet spinning machines have enhanced filtration systems that can easily handle different polymers and additives, ensuring

high-quality output. Furthermore, energy efficiency has become a focal point,

with many machines designed to minimize power consumption without compromising performance. Features such as rapid startup times

and user-friendly interfaces also contribute to their appeal, making them indispensable tools for modern fiber production facilities.

Comparison of Performance and Efficiency Among Leading Models

When selecting a wet spinning machine for fiber production, performance and efficiency are paramount. Recent advancements in technology have introduced models that optimize energy consumption while enhancing the quality of the spun fibers. Key factors to evaluate include the machine's throughput, fiber uniformity, and the ease of maintenance. Many leading models now feature automated controls that facilitate precision in spinning, allowing for consistent results across various fiber types.

Tips: To maximize production efficiency, operators should regularly monitor machine settings and conduct routine maintenance checks. This helps maintain the precision of the spinning process and prevents unexpected downtimes. Additionally, experimenting with different spinning speeds can yield insights into the optimal settings for achieving desired fiber characteristics while minimizing energy use.

Furthermore, the comparison of various machines often reveals differences in their adaptability to various materials. Some models are better suited for synthetic fibers, while others excel with natural. Understanding the specific requirements of the materials being processed can lead to improved efficiency and fiber quality. It's also beneficial to consider the environmental impact of the spinning process, as modern machines are increasingly designed to be eco-friendly, reducing waste and energy consumption without sacrificing performance.

Maintenance Tips for Optimal Performance of Wet Spinning Machines

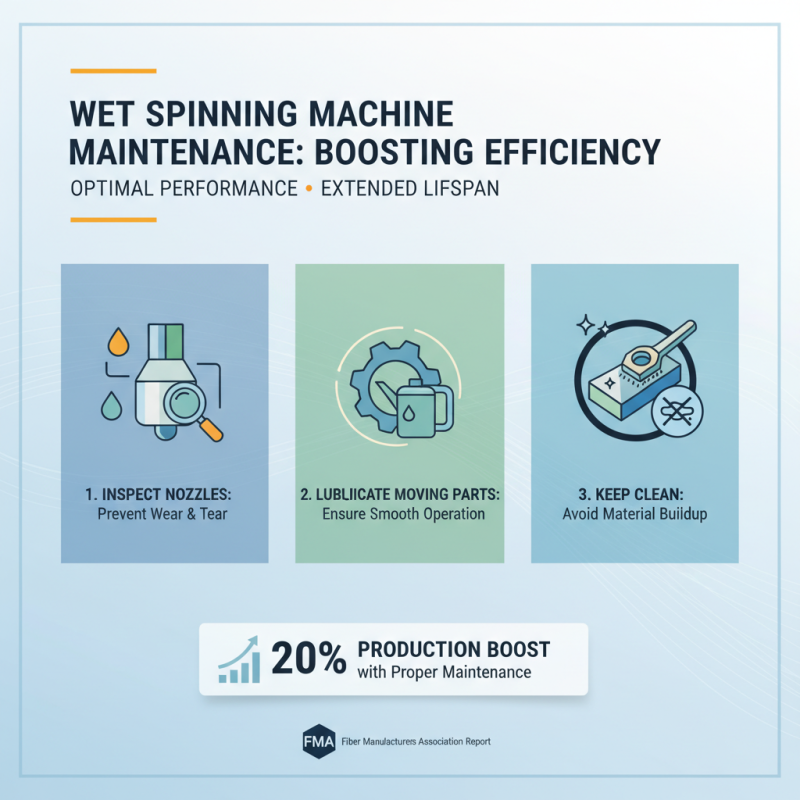

Maintaining wet spinning machines is crucial for achieving optimal performance and ensuring efficient fiber production. Regular maintenance not only extends the life of the machines but also enhances their operational efficiency. According to a report by the Fiber Manufacturers Association, improper maintenance can lead to a 20% decrease in production efficiency, highlighting the importance of a structured maintenance plan. Key maintenance tasks include regular lubrication of moving parts, inspection of the spinning nozzles for wear and tear, and keeping the machine clean to prevent material buildup that could hinder performance.

Moreover, monitoring the temperature and humidity levels in the production environment is vital to maintain the quality of the spun fibers. A study published in the Journal of Textile Engineering indicated that maintaining optimal humidity levels can reduce the risks of machine jams and fiber breakage by up to 15%. Additionally, operators should be trained to conduct routine checks and adjustments, as even minor issues can escalate into major problems if left unaddressed. Implementing predictive maintenance strategies using data analytics can also significantly enhance the operational reliability and efficiency of wet spinning machines, ensuring a consistent quality of fiber production.

Related Posts

-

Top 5 Benefits of Using Industrial Fabric Laser Cutting Machines for Your Business

-

Why Investing in Textile Machinery is Essential for Modern Manufacturing Success

-

Revolutionize Your Business with Advanced Industrial Fabric Printing Machines: Trends and Tips for Success

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production

-

Top Fabric Coating Machines of 2025: Key Features and Buying Guide

-

Top 10 Digital Textile Printing Machines to Enhance Your Printing Business