Why You Need a Carding Machine for Your Textile Production Efficiency

In the fast-evolving textile industry, the efficiency of production processes is paramount. One of the key players in enhancing this efficiency is the carding machine. As emphasized by expert Dr. Emily Harris, a leading figure in textile engineering, "The carding machine is not just a piece of equipment; it’s the backbone of textile manufacturing, ensuring fiber quality and uniformity." This statement underscores the importance of carding machines in optimizing production workflows and achieving high-quality outputs.

Carding machines serve as the first stage in the textile production process, where raw fibers are transformed into a more manageable form. By effectively disentangling and aligning fibers, these machines lay the groundwork for subsequent operations such as spinning and weaving. With advancements in technology, modern carding machines offer enhanced capabilities, including increased automation and precision, which are crucial for meeting the demands of today’s market.

Investing in a carding machine can significantly improve production efficiency, reduce waste, and elevate the overall quality of textile products. As textile producers face growing competition and the need for sustainability, recognizing the value of carding machines becomes essential for maintaining a competitive edge in the industry.

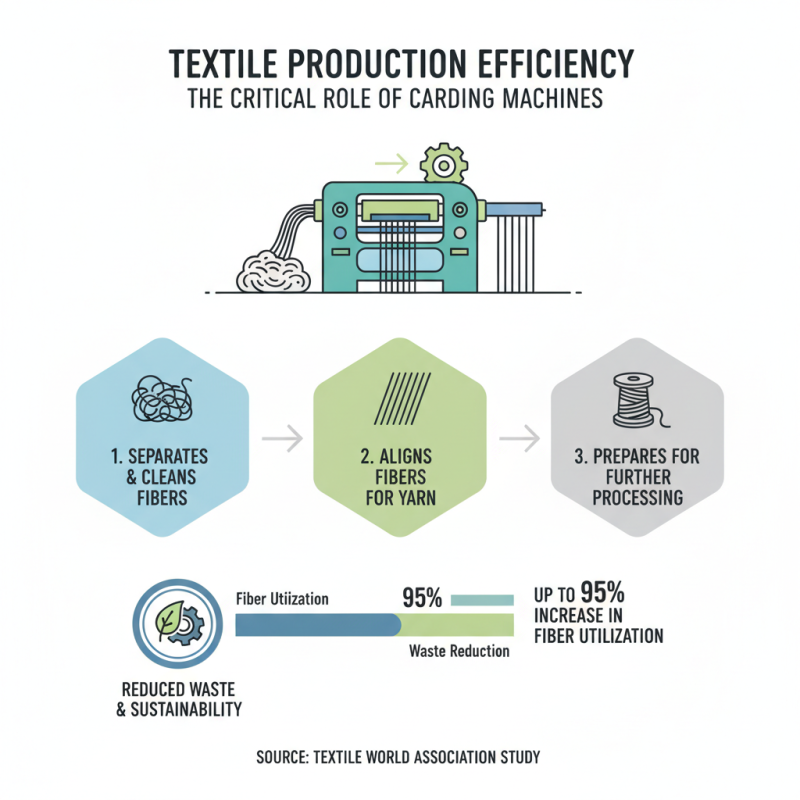

The Importance of Carding Machines in Textile Production

The importance of carding machines in textile production cannot be overstated, as they play a critical role in enhancing the overall efficiency of the manufacturing process. Carding is the first mechanical process in turning raw fibers into usable yarn, and it serves to separate, clean, and align the fibers before they undergo further processing. According to a study published by the Textile World Association, effective carding can increase fiber utilization by up to 95%, significantly reducing waste and promoting sustainability in textile manufacturing.

Additionally, the efficiency of carding machines is crucial for maintaining consistent quality in produced textiles. Research by the International Journal of Textile Science has shown that high-quality carding leads to uniform yarn production, which ultimately impacts the final fabric strength and appearance. Advanced carding technologies, incorporating automation and precision engineering, have been reported to enhance production speeds by approximately 30-40%, thus enabling manufacturers to meet increasing demands without compromising quality. As the textile industry faces rising competition and consumer expectations, investing in modern carding machines becomes essential for maintaining a competitive edge.

How Carding Machines Enhance Production Efficiency

Carding machines play a crucial role in enhancing efficiency in textile production, primarily by transforming raw fibers into a more manageable form for further processing. This essential step not only improves fiber alignment but also removes impurities and prepares the material for spinning. According to the International Textile Manufacturers Federation, updated methodologies in carding can lead to a 20% increase in throughput, directly impacting production rates and overall profitability.

Utilizing a modern carding machine also reduces labor costs by minimizing the need for manual intervention during fiber processing. Automation in carding has been reported to decrease labor requirements by up to 30%, freeing workers to focus on more complex and skilled tasks elsewhere in the production line. A recent study from the Textile Research Journal highlighted that facilities adopting advanced carding technology experienced a significant reduction in operational downtime, further maximizing their output potential.

**Tip:** Regular maintenance of carding machines is key for sustaining their efficiency. Ensuring that components are clean and well-lubricated can prevent breakdowns and extend the lifespan of the equipment. Another beneficial practice is training staff on best practices for loading and unloading fibers, which can streamline the workflow and enhance overall productivity.

Key Features of Modern Carding Machines

Modern carding machines have revolutionized textile production by enhancing efficiency and consistency in the fiber preparation process. One of the key features of contemporary carding technology is automation, which allows for real-time monitoring and adjustments during operation. This minimizes human error and significantly reduces the time required for setup and maintenance. Additionally, advanced carding machines are equipped with sophisticated software that can analyze production data, helping manufacturers identify areas for improvement and optimize workflows for greater output.

Another important aspect of modern carding machines is their ability to handle a diverse range of fibers, from natural to synthetic materials. This versatility ensures that textile producers can switch between different products without needing to invest in multiple specialized machines. Furthermore, modern carding machines often include enhanced fiber opening and blending capabilities, which improve the overall quality of the final product by ensuring even distribution of fibers. The implementation of energy-efficient motors and designs also contributes to reduced operational costs, making them an essential investment for any textile manufacturing facility aiming to stay competitive.

Comparative Analysis: Manual vs. Automated Carding Processes

The choice between manual and automated carding processes significantly influences textile production efficiency. Manual carding, while rooted in traditional practices, often entails labor-intensive work. Workers must skillfully manage the carding tools, which can lead to inconsistencies in fiber quality and longer processing times. These factors can slow down production rates, resulting in higher operational costs and potential delays in meeting market demands.

In contrast, automated carding machines streamline the entire process, enhancing efficiency and uniformity. These machines are designed to handle larger volumes of fibers with precision, reducing human error and the variability associated with manual methods. Automation not only speeds up production but also frees operators from repetitive tasks, allowing them to focus on more complex aspects of textile manufacturing. By implementing automated carding, manufacturers can achieve higher throughput and consistent product quality, ultimately leading to greater competitiveness in the textile market.

Future Trends in Carding Technology for Textile Manufacturing

The carding process is crucial to textile manufacturing, serving as the first step in transforming raw fibers into usable products. Recent trends in carding technology indicate a significant shift towards automation and integration of smart technologies. According to a report by the International Textile Manufacturers Federation (ITMF), approximately 60% of current textile production facilities are investing in automated carding systems to enhance productivity and reduce labor costs. These advancements not only streamline operations but also improve the quality of the yarn produced, ensuring a more uniform texture.

Moreover, sustainability in textile manufacturing is becoming increasingly vital. The global demand for eco-friendly production methods has prompted the development of carding machines that utilize energy-efficient technologies and minimize waste. A study by the Textile Research Institute revealed that modern carding machines can reduce energy consumption by up to 30%, while also significantly decreasing material waste during the carding process. This pivot towards sustainable practices is essential for manufacturers aiming to meet both consumer expectations and regulatory standards.

In addition, the integration of data analytics and machine learning into carding technology allows manufacturers to optimize operations in real time. Through the use of sensors and IoT devices, companies can monitor the carding process, identify bottlenecks, and implement corrective measures instantly. This data-driven approach leads to improved efficiency and consistency, solidifying the role of advanced carding machines as a cornerstone of future textile production.

Impact of Carding Machines on Textile Production Efficiency (2023)

Related Posts

-

What is a Fabric Recycling Machine and How Does It Benefit the Environment

-

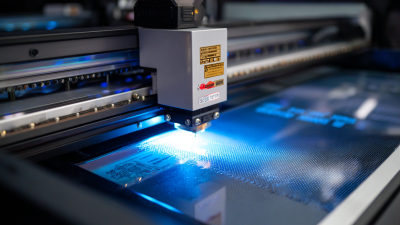

How to Choose the Best Fabric Laser Cutting Machine in 2025

-

How to Effectively Use Textile Waste Recycling Machine for Sustainable Practices

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production

-

Top 10 Best Weaving Machines for Efficient Textile Production