Why Choose an Industrial Fabric Printing Machine for Your Business?

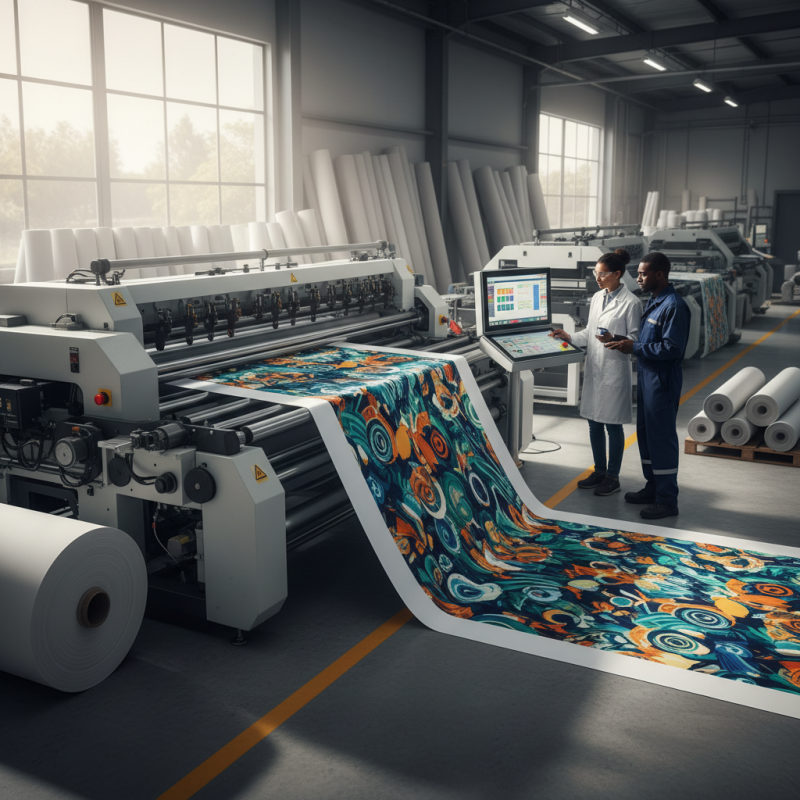

In the evolving landscape of textile production, the choice to invest in an industrial fabric printing machine can significantly impact your business. Renowned industry expert, Dr. Emily Carter, emphasizes, “The right printing technology opens doors to creativity and efficiency.” This statement rings true as businesses seek ways to differentiate themselves in a competitive market.

An industrial fabric printing machine offers precision and versatility. With advanced technology, these machines allow vibrant prints and complex designs on various fabrics. This level of customization is crucial for brands aiming to create a unique identity. However, businesses must carefully evaluate their needs and budget before investing. Sometimes, the initial cost can be daunting, yet the long-term benefits can outweigh these challenges.

Transitioning to an industrial fabric printing machine also requires training and a change in workflow. Companies might face hurdles during this process. Adaptation can take time, but the potential for increased production and creativity is worth the investment. It’s essential to recognize these challenges as opportunities for growth and reflection. Embracing this technology can prepare businesses for the future of fabric printing.

Benefits of Industrial Fabric Printing Machines for Customization Needs

Industrial fabric printing machines are revolutionizing the customization landscape. They enable businesses to create unique designs tailored to customer preferences. With the global market for fabric printing projected to reach approximately $3.35 billion by 2026, the demand for personalized products is evident. Companies that embrace this technology gain a competitive edge.

Customization needs are at the forefront of consumer desires. According to a recent study, 70% of consumers prefer products that reflect their unique style. Industrial fabric printing allows for intricate designs and vibrant colors, enhancing product appeal. Businesses can create everything from bespoke apparel to eye-catching home decor. Engaging with customers through personalized designs strengthens brand loyalty, driving repeat business.

Tips: Start small. Test different fabrics and designs before a full rollout. Monitor customer feedback closely. It's crucial to adapt quickly based on market responses. Remember, not every design will resonate equally. Focus on quality, even if it means slower production initially. Balancing creativity with practicality is key for success.

Market Growth Trends in the Industrial Fabric Printing Sector

The industrial fabric printing sector is witnessing remarkable growth. Reports from industry analysts forecast a compound annual growth rate (CAGR) of about 7.5% from 2021 to 2026. This expansion is driven by the increasing demand for customized textiles in various applications. These applications range from interior décor to fashion apparel. Businesses are recognizing the potential of industrial fabric printing as a game changer.

Tips: Consider investing in a fabric printing machine tailored to your production needs. Analyze your target market to determine the best fabrics and designs.

Companies are also adopting eco-friendly printing solutions. Sustainable practices are now essential in attracting consumers. Moreover, advancements in printing technology enhance the quality and speed of production. However, some businesses may struggle with integrating these new systems. The initial investment can be daunting, and transitioning requires staff training.

Tips: Start with small-scale projects to test the market. Collect feedback from customers to refine your offerings. Staying flexible is key. The evolving industry landscape can be both a challenge and an opportunity. Adaptation will be crucial for long-term success.

Cost Efficiency Analysis of In-House Fabric Printing Solutions

Investing in an industrial fabric printing machine can significantly enhance your business operations. This choice is often driven by the cost efficiency of in-house printing solutions. By eliminating outsourcing costs, businesses can save money over time. There is also the benefit of reduced turnaround times. Immediate access to fabric printing can speed up production cycles.

However, the initial costs can be daunting. Acquiring high-quality machines requires financial commitment. It's essential to analyze your production needs before making a purchase. A miscalculation might lead to underutilization of the equipment. This can result in wasted resources and increased operating expenses.

On the other hand, maintaining in-house printing opens avenues for creative control. It allows businesses to adapt designs quickly. Flexibility in production can cater to changing customer demands. That said, it is important to stay updated with technology. Equipment may require upgrades over time, which can add to costs. Regular assessment of your printing needs can help sustain efficiency.

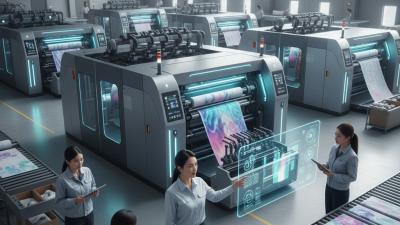

Technological Advancements in Fabric Printing Machinery

The landscape of fabric printing is rapidly evolving thanks to technological advancements. Modern industrial fabric printing machines now offer high-resolution outputs, vibrant colors, and efficient production speeds. These machines can handle various fabric types, from cotton to polyester. The flexibility in material compatibility allows for diverse applications, catering to different business needs.

Integration of digital printing technology has transformed workflow dynamics. Businesses can create custom designs more quickly than ever. However, this does require a learning curve. Operators often need training to maximize their machine's capabilities. This transition can be challenging for teams accustomed to traditional methods. The potential for errors in design and setup is increased as users adapt to new software and hardware requirements.

Despite these challenges, the benefits are undeniable. Enhanced production speeds mean quicker turnaround times for orders. This speed can significantly boost productivity. Additionally, reduced waste in material usage translates to cost savings. Yet, businesses must reflect on their readiness to invest in this technology. Upfront costs can be high, and not all companies may find it worthwhile immediately. The choice to upgrade should be carefully considered.

Environmental Considerations and Sustainability in Fabric Printing

Industrial fabric printing is gaining attention for its sustainability. The textile industry is one of the largest polluters in the world. Reports indicate that it contributes to over 20% of global wastewater. This alarming statistic highlights the need for eco-friendly practices.

Using an industrial fabric printing machine can significantly reduce waste. Traditional printing methods often produce excess dyes and chemicals. In contrast, digital fabric printing utilizes less water and fewer resources. Studies show it can lower water usage by up to 90%. This efficiency benefits both the environment and a company’s bottom line. However, it's essential to acknowledge that not all machines are equal. Some machines still use harmful inks, which can negate sustainability efforts.

Sustainability goes beyond the printing process itself. The materials used also play a crucial role. Many fabrics are made from non-renewable resources. However, a shift towards organic and recycled materials is observable. Reports indicate that the demand for sustainable fabrics is increasing by about 20% annually. This trend reflects changing consumer preferences. While progress is being made, the industry still has room for improvement in sourcing and production practices. Balancing efficiency with sustainability remains a challenge.

Why Choose an Industrial Fabric Printing Machine for Your Business? - Environmental Considerations and Sustainability in Fabric Printing

| Dimension | Value | Environmental Benefit |

|---|---|---|

| Ink Type | Water-based Inks | Lower VOC emissions |

| Power Consumption | 500 W - 2000 W | Efficient energy use |

| Waste Material | Less than 5% | Reduced landfill impact |

| Recyclability | Up to 100% | Promotes circular economy |

| Chemical Usage | Minimal | Safer for operators and environment |

| Production Speed | 20-100 m²/h | Increased efficiency reduces resource use |

Related Posts

-

Top 10 Digital Textile Printing Machines to Enhance Your Printing Business

-

2025 Top 10 Textile Printing Machines Revolutionizing the Industry

-

Top 10 Fabric Printing Machines for High Quality Custom Designs

-

Top 10 Best Wet Spinning Machines for Efficient Fiber Production in 2023

-

Why You Need a Carding Machine for Your Textile Production Efficiency

-

Top Fabric Coating Machines of 2025: Key Features and Buying Guide