How to Choose the Best Fabric Laser Cutting Machine for Your Business

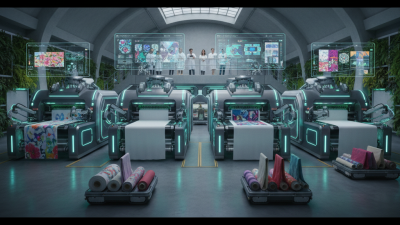

In the rapidly evolving textile industry, the demand for precision and efficiency has led businesses to seek advanced technological solutions. One such innovation, the fabric laser cutting machine, has transformed traditional cutting processes by offering unparalleled accuracy and versatility. According to a recent market report from ResearchAndMarkets.com, the global textile laser cutting machine market is projected to reach USD 1.7 billion by 2025, growing at a compound annual growth rate (CAGR) of 10.4%. This growth is driven by the increasing need for sustainable manufacturing practices and the rising adoption of automation in textile production.

When selecting the best fabric laser cutting machine for your business, it is essential to consider various factors that align with your operational needs and future growth. Leading manufacturers are continuously enhancing their technologies, which not only improves cutting precision but also reduces material waste—a critical concern in an industry that is increasingly focused on sustainable practices. As businesses strive to maintain competitiveness, understanding the top contenders in this market will empower decision-makers to invest wisely, ensuring that their production capabilities meet both current demands and future opportunities. This guide will explore the top 10 fabric laser cutting machines of 2025, providing insights that can help businesses navigate their choices effectively.

Key Features to Look for in a Fabric Laser Cutting Machine

When selecting a fabric laser cutting machine for your business, it's crucial to focus on key features that will enhance your production efficiency. One of the primary elements to consider is the laser power. According to industry reports, machines with higher wattage, typically ranging from 60W to 150W, facilitate faster cutting speeds and ensure cleaner cuts, especially for thicker materials. This capability directly correlates with productivity; for instance, businesses using higher-powered lasers can increase their output by up to 30%, compared to those utilizing lower-powered systems.

Another vital feature is the cutting area size. A larger workspace allows for cutting larger pieces of fabric without the need for multiple setups, which can save significant time and labor costs. The Global Laser Cutting Market Report indicates that companies that invest in machines with versatile cutting areas can achieve a reduction in material waste by approximately 20%. Additionally, user-friendly software integration is essential for seamless operations. Machines equipped with advanced software can facilitate precise designs and expedite the transition from digital to physical products, leading to improved overall workflow efficiency.

Understanding Different Laser Technologies for Fabric Cutting

When selecting a fabric laser cutting machine, understanding the different laser technologies available is crucial for optimizing your business operations. The two most common types of lasers used in fabric cutting are CO2 lasers and fiber lasers. CO2 lasers are well-suited for cutting various fabrics, including cotton, silk, and synthetics. They operate at a wavelength that is easily absorbed by organic materials, producing clean cuts and minimal fraying. This technology is a preferred choice for businesses that work with delicate fabrics or require intricate designs.

On the other hand, fiber lasers offer advantages particularly for high-speed cutting of industrial fabrics and materials with reflective properties, such as polyester and nylon. They operate at a shorter wavelength, which allows for greater precision and efficiency in cutting. Moreover, fiber lasers typically have lower maintenance costs and a longer operational lifespan compared to CO2 lasers. By understanding these differences, businesses can make informed decisions when investing in a laser cutting machine that aligns with their specific fabric processing needs.

Comparing Costs: Budgeting for Your Fabric Laser Cutting Investment

When considering the investment in a fabric laser cutting machine, budgeting is a crucial aspect that can influence your overall business operations. The initial cost of these machines can vary significantly based on factors such as brand, technology, and features. For small businesses or startups, it's essential to assess not just the purchase price but also the long-term operational costs, including maintenance, consumables, and energy consumption. Establishing a thorough budget will help you make informed decisions that align with your financial capabilities.

In addition to the initial investment, potential buyers should evaluate the return on investment (ROI) that a fabric laser cutting machine can provide. By increasing production efficiency and reducing waste, a high-quality laser cutter can lead to substantial cost savings over time. Analyze your production needs and calculate how quickly you can expect to recoup your investment. This analysis will assist in selecting a machine that not only fits your current budget but also serves your business growth for years to come.

How to Choose the Best Fabric Laser Cutting Machine for Your Business

| Feature | Budget Model | Mid-Range Model | High-End Model |

|---|---|---|---|

| Price Range | $5,000 - $10,000 | $10,001 - $20,000 | $20,001 - $50,000 |

| Cutting Speed (mm/s) | 600 | 800 | 1200 |

| Maximum Cutting Width (mm) | 600 | 1200 | 1800 |

| Software Compatibility | Basic Software | Intermediate Software | Advanced Software |

| Warranty Period | 1 Year | 2 Years | 3 Years |

| Customer Support | Limited | Standard | Priority |

Assessing Machine Size and Compatibility with Your Workspace

When selecting a fabric laser cutting machine for your business, assessing the machine's size and workspace compatibility is crucial. Industry reports indicate that an optimal workspace not only enhances productivity but also reduces operational risks. According to a study by the Fabrics and Textile Institute, businesses that strategically arrange their equipment in a well-planned space can see a productivity increase of up to 30%. Therefore, measuring your workspace dimensions and planning for adequate clearance around the machine can significantly impact your operational efficiency.

Furthermore, considering the machine's dimensions is equally important. A laser cutter must fit seamlessly into your current setup to avoid workflow disruptions. A comprehensive report from the American Laser Institute emphasizes that an improperly sized machine can lead to wasted time and increased costs, estimating that 15% of small to medium enterprises face such challenges. Hence, it's advisable to consider machines designed for specific fabric types and usage requirements while ensuring they won’t overcrowd your workspace. Analyzing these factors will ultimately lead to smarter investments in laser cutting technology.

Evaluating Customer Support and Warranty Options for Longevity

When selecting a fabric laser cutting machine, evaluating customer support and warranty options is crucial for the longevity of your investment. A reliable manufacturer should provide comprehensive customer support to assist you with installation, operation, and maintenance. Look for companies that offer multiple channels for support, such as email, phone, and live chat, ensuring you can get help promptly when needed.

Tips: Before finalizing your purchase, inquire about the availability of technical support during business hours and whether they offer training sessions for your staff. Additionally, research online reviews to see how other users rate the support experience.

Warranty options can greatly influence your choice. A robust warranty not only protects your machine against defects but also indicates the manufacturer's confidence in their product. It’s advisable to choose a machine with an extended warranty that covers essential components, such as the laser and optics.

Tips: Check the terms and conditions of the warranty carefully. Some warranties may include on-site support or coverage for wear and tear, which can save you significant costs in the long run.

Comparison of Key Factors for Fabric Laser Cutting Machines

Related Posts

-

How to Effectively Use Textile Waste Recycling Machine for Sustainable Practices

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production

-

Top 10 Digital Textile Printing Machines to Enhance Your Printing Business

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production

-

Revolutionize Your Business with Advanced Industrial Fabric Printing Machines: Trends and Tips for Success