How to Choose the Right Industrial Weaving Machine for Your Needs?

Choosing the right industrial weaving machine is crucial for any textile business. According to Dr. Emily Chen, an expert in textile technology, "Selecting the right machine can enhance efficiency and product quality." With numerous options available, it can be overwhelming for producers.

Consider the type of fabrics you plan to weave. Different machines cater to specific materials like silk, cotton, or synthetic fibers. Investing in the wrong machine may lead to subpar results and lost resources. It's essential to understand your production needs fully.

Additionally, think about the machine's capacity and your production volume. A machine suited for small batches may not keep up with large-scale demands. Reflecting on these factors can streamline your decision-making. Your chosen industrial weaving machine should align with your unique requirements for optimal success.

Understanding Your Weaving Needs and Objectives

Choosing the right industrial weaving machine starts with understanding your needs. Consider the type of fabric you plan to produce. Are you focusing on lightweight textiles or heavy-duty materials? This choice heavily influences the machine's required speed and power. According to industry reports, a proper alignment of machinery with production goals can boost efficiency by up to 30%.

Tips: Assess your production volume. High-volume demands require faster machines, while lower outputs may allow for more versatile options. Also, consider the types of patterns you want to create. Some machines excel in complex weaves, while others might be more suited for basic designs.

It's crucial to reflect on technical specifications as well. Quality machines have varied features like programmable controls or material handling capabilities. However, some operators often overlook the complexity of maintenance. Industry experts indicate that routine checks can prevent up to 50% of unexpected downtimes. Balancing capability with usability and upkeep should drive your decision.

Types of Industrial Weaving Machines Available

Choosing the right industrial weaving machine can be daunting. There are various types designed for different applications. For instance, shuttle looms are widely used for weaving heavy fabrics. These machines offer durability and a robust build. A report by Market Research Future highlighted that shuttle looms are expected to grow by 5% annually.

Another option is shuttleless looms, which include air-jet and rapier looms. These are faster and more efficient, catering to lighter fabrics. The global market for shuttleless looms was valued at over $2 billion in 2022. They allow for complex patterns, appealing to manufacturers targeting niche markets. However, the initial investment is significant, and maintenance can be tricky.

Lastly, there are Jacquard looms, ideal for intricate designs. They allow for high levels of customization. According to a survey, about 30% of weavers face challenges with their Jacquard machines. This might stem from the intricate programming required. Each machine type has its unique pros and cons. Understanding these nuances can help in making an informed choice, aligning your production needs with your budget.

Key Features to Consider When Selecting a Weaving Machine

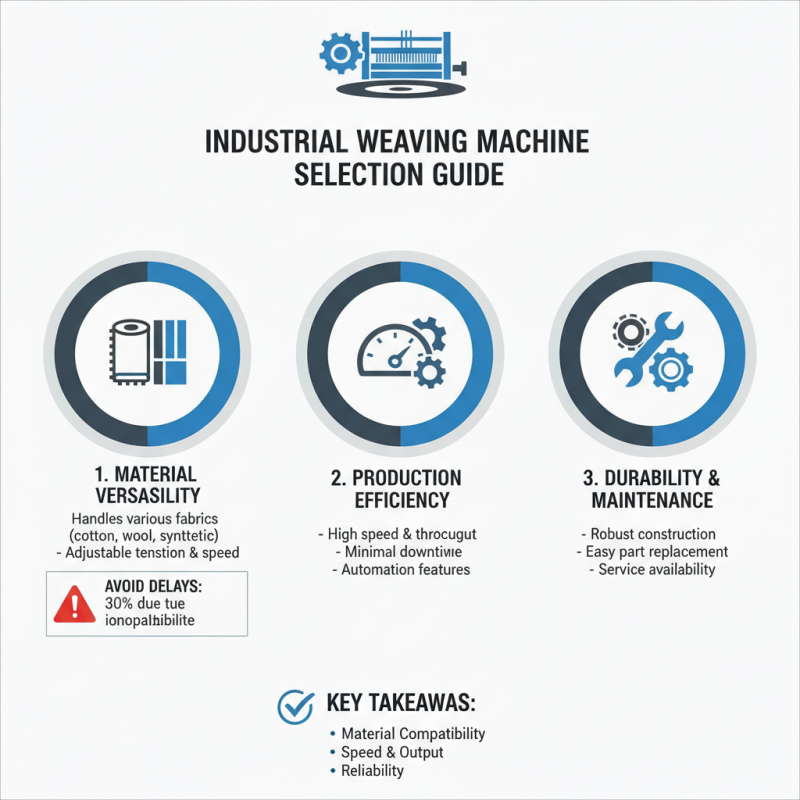

Choosing the right industrial weaving machine can significantly impact your production efficiency. When selecting a machine, key features warrant careful consideration. First, assess the machine's capability to handle various materials. Different fabrics require specific tension and speed settings for optimal weaving. According to industry reports, more than 30% of production delays arise from incompatible machine-fabric pairings.

Next, look into the machine's automation features. The trend towards automation has grown substantially. Research indicates that automated weaving machines can boost productivity by up to 50% compared to manual setups. This efficiency can lead to shorter lead times and reduced labor costs. However, an advanced machine may necessitate higher initial investment and specialized training for operators.

Don't overlook service and maintenance options. Machines with complex technology can be challenging to maintain. Data shows that about 20% of downtime in weaving operations is due to maintenance issues. Ensure that the chosen machine is supported by accessible service and spare parts. Finding the right balance of features, efficiency, and support is crucial. It may require some experimentation to identify a machine that perfectly fits your production needs.

Assessing Budget and Cost-Effectiveness in Your Purchase

When planning to buy an industrial weaving machine, budget plays a crucial role. Industry reports suggest that prices can vary widely, with some machines costing as little as $10,000 and others exceeding $100,000. Manufacturers should carefully assess their production scale. Larger operations might feel justified investing in high-end models. Yet, small to mid-sized businesses often discover that budget machines suffice for their needs.

Cost-effectiveness is also about efficiency. A reliable machine can reduce waste and improve production speed. According to recent studies, a machine capable of producing 50 meters of fabric per hour could help a company save up to 20% on labor costs. However, a cheaper option that breaks down frequently might lead to increased production downtime and repair costs.

Consider the long-term implications. A machine priced at $30,000 might seem daunting, but if it lasts five years without major repairs, it could be more economical than a $15,000 machine that requires frequent service. In addition, think about energy consumption. More efficient machines may have higher upfront costs but can lead to substantial savings over time. Balancing initial expenses with potential savings is essential for making a sound decision.

Maintenance and Support Considerations for Weaving Machines

When selecting an industrial weaving machine, maintenance and support play crucial roles. Regular maintenance ensures your machine operates efficiently. Without proper care, performance can decline. This often leads to costly downtime.

Tips: Establish a maintenance schedule. Inspect components monthly. Clean the machine regularly. Small issues can turn into major problems if left unchecked. Keeping up with maintenance can save time and money.

Support is equally important. A reliable support system can help address issues promptly. Look for suppliers that offer comprehensive support, including training for staff. Understanding your equipment is vital. Not all machines are the same. Some may require unique service techniques.

Tips: Research support options before purchasing. Read reviews to understand the quality of assistance. Evaluate the availability of spare parts. A machine may need repairs sooner than expected.

Industrial Weaving Machine Maintenance Frequency

Related Posts

-

Top 10 Best Weaving Machines for Efficient Textile Production

-

What is a Fabric Recycling Machine and How Does It Benefit the Environment

-

Revolutionize Your Business with Advanced Industrial Fabric Printing Machines: Trends and Tips for Success

-

Top 5 Benefits of Using Industrial Fabric Laser Cutting Machines for Your Business

-

Top Fabric Coating Machines of 2025: Key Features and Buying Guide

-

2025 How to Choose the Best Weaving Machine for Your Business Needs