2025 How to Choose the Best Weaving Machine for Your Business Needs

Choosing the right weaving machine is a crucial decision that can significantly impact the efficiency and productivity of your textile business. With the diverse range of weaving machines available in the market, it's essential to understand your specific business needs and the various features that different machines offer. Whether you are a small-scale artisan or managing a large manufacturing unit, the right weaving machine can enhance your operational capabilities and improve the quality of your products.

In this guide, we will explore the key factors to consider when selecting a weaving machine, including the types of fibers you intend to work with, the volume of production required, and the complexity of the designs you want to create. Weaving machines come with varying technologies and specifications, which can cater to different weaving techniques such as jacquard, dobby, or plain weave. Understanding these fundamental aspects will help you make an informed decision that aligns with your business goals and boosts your competitive edge in the textile industry.

Understanding Different Types of Weaving Machines Available in 2025

In 2025, understanding the diverse range of weaving machines available is crucial for businesses looking to enhance their production capabilities. The weaving machinery market is expected to continue its growth trajectory, with a projected increase of approximately 8% annually through 2027, according to industry reports. This growth is driven by advancements in technology and increasing demand for high-quality textiles across various sectors, including fashion, home furnishings, and industrial applications.

When selecting the right weaving machine, businesses should first consider the type of fabric they intend to produce. Broadly, weaving machines can be categorized into traditional shuttle looms, modern air-jet looms, and rapier looms, each offering distinct advantages. For instance, air-jet looms are renowned for their speed and efficiency, capable of producing intricate patterns and textures at a rate of up to 900 fabric picks per minute. Conversely, rapier looms are favored for their versatility in handling a wide range of yarn types and project specifications. As reported by textile industry analysts, approximately 45% of manufacturers are now opting for air-jet models to meet the increasing demands for synthetic fabrics and complex weaves.

Moreover, businesses must evaluate the automation features offered by modern weaving machines. Automated systems not only enhance production reliability but also significantly reduce labor costs by up to 30%, as highlighted in recent market research. As automation becomes more prevalent, companies will need to align their operational strategies to leverage these advancements effectively, thus achieving higher productivity levels while minimizing waste and maintaining quality standards.

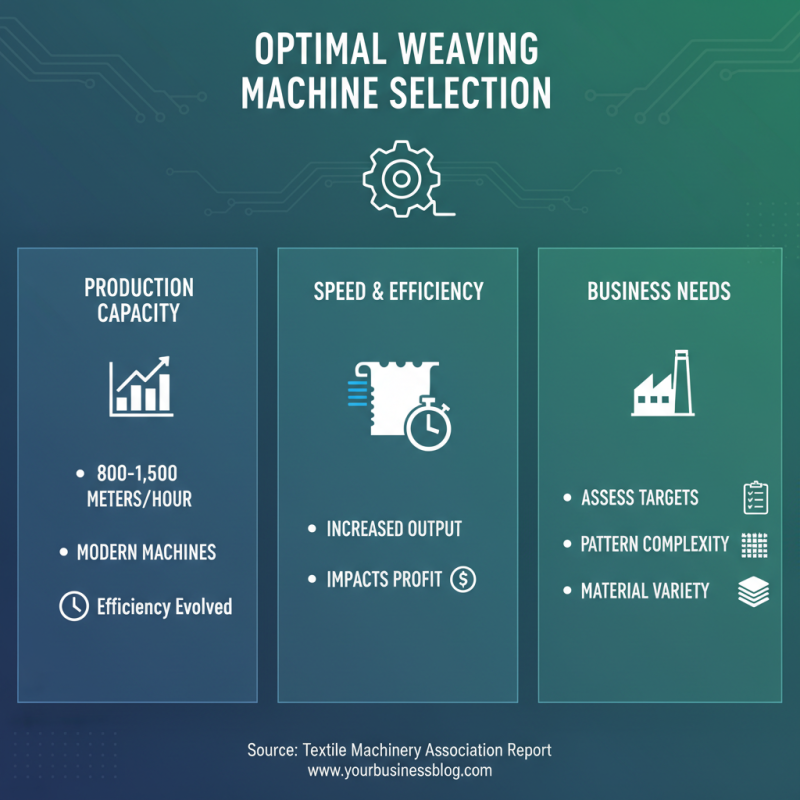

Evaluating Production Capacity and Speed for Your Business Requirements

When selecting the best weaving machine for your business needs, evaluating production capacity and speed is paramount. According to a report by the Textile Machinery Association, the efficiency of weaving machines has significantly evolved, with modern models capable of producing between 800 and 1,500 meters of fabric per hour. This advancement directly affects your operational capacity and ultimately your bottom line. Businesses need to assess their production targets and ensure the selected machine aligns with desired output levels, taking into account factors such as the complexity of the patterns and the variety of materials used.

In addition to production speed, it is essential to consider how these machines perform under different workloads. A study published by the International Textile Research Institute indicates that machines designed for higher production speeds often maintain quality control under heavy usage. The same report emphasizes that investing in machines with faster production capabilities can lead to a return on investment (ROI) of approximately 35% over three years. Thus, when evaluating weaving machines, understanding both the speed and the capacity to maintain quality standards during operation can significantly influence long-term profitability and customer satisfaction.

Assessing Fabric Types and Weaving Techniques for Optimal Results

When selecting a weaving machine for your business, it’s crucial to assess the types of fabrics you plan to work with and the weaving techniques that will yield the best results. Different fabrics, such as cotton, silk, or synthetic blends, require specific machine capabilities. For instance, according to the Textile World report, high-quality weaving machines can handle diverse fabric types, increasing production efficiency by up to 30%. Understanding the nature of the fabrics helps in choosing a machine that can operate at optimal speeds without compromising fabric quality.

Tips: Before making a decision, conduct a thorough analysis of the yarn types you will utilize. If you’re looking to produce intricate patterns, consider weaving machines equipped with advanced shuttle or Jacquard capabilities, which enhance design versatility. Additionally, reviewing production volume and machine speed can ensure that the selected weaving machine aligns with your business goals.

Different weaving techniques, such as twill or satin, also influence machine choice. For instance, a report by the International Textile Manufacturers Federation (ITMF) suggests that machines designed for specific techniques can produce high-quality outcomes with fewer errors—a critical factor in maintaining production standards. As you evaluate your options, ensure that the machine offers adaptability to various techniques, facilitating your ability to innovate within the market.

2025 Weaving Machine Analysis: Fabric Types and Weaving Techniques

Considering Budget and Cost-Efficiency in Machine Selection

When selecting a weaving machine for your business, one of the foremost considerations should be your budget. Understanding your financial constraints helps narrow down the options, allowing you to focus on machines that provide the best value for your investment. Assessing the initial purchase cost is just as important as evaluating ongoing operational costs. A more expensive machine might offer advanced features and higher efficiency, but if it stretches your budget too thin, it may not be the best choice for your business.

Cost-efficiency also encompasses maintenance and repair expenses, which can significantly affect long-term operational budgets. Look for weaving machines that offer reliability and durability to minimize downtime and the need for repairs. Additionally, factor in the potential return on investment; some machines, while initially pricier, can lead to higher productivity and lower labor costs, ultimately justifying the initial expense. Striking a balance between upfront costs and long-term savings is essential for making a well-informed and strategic decision for your business's needs.

Researching Manufacturer Reputation and After-Sales Support Options

When selecting a weaving machine for your business, researching the manufacturer’s reputation and their after-sales support options is crucial. A recent report from Technavio indicates that the global textile manufacturing machinery market is expected to grow by over 5% annually until 2025. With such growth projected, choosing a manufacturer with a strong reputation can significantly impact your business’s long-term success. Companies backed by positive customer feedback and extensive industry experience tend to offer more reliable machines that can operate efficiently over time.

In addition to reputation, evaluating after-sales support options is essential. According to a survey by the Textile Machinery Association, around 78% of textile businesses consider after-sales service as a key factor in their purchasing decision. This support often includes maintenance services, availability of spare parts, and training for operators. A strong after-sales service can reduce downtime and improve overall production efficiency, making it imperative to partner with manufacturers that prioritize customer service and technical support. Ensuring that you have dependable resources at hand can help your business navigate the complexities of machine operation and maintenance effectively.

Related Posts

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

Top 10 Best Weaving Machines for Efficient Textile Production

-

2025 Top 10 Textile Printing Machines Revolutionizing the Industry

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production

-

Top 10 Fabric Printing Machines for High Quality Custom Designs

-

How to Choose the Best Fabric Laser Cutting Machine for Your Business