Why Choosing the Right Fabric Making Machine is Essential for Your Business Success

In today's fast-paced textile industry, the choice of a fabric making machine can significantly impact a business's operational efficiency and overall success. As industry expert Dr. Emily Carter, a leading authority in textile manufacturing, aptly states, “The right fabric making machine can turn a simple idea into a successful product, shaping not just the fabric but the future of a business.” This rings particularly true as manufacturers navigate the complexities of modern production demands and sustainability initiatives.

Investing in the appropriate fabric making machine not only affects production quality but also influences cost management and environmental impact. As competition intensifies, businesses must ensure that their machinery aligns with their operational goals and market expectations. Selecting the right equipment entails understanding the nuances of fabric types, production speed, and technological advancements that can enhance productivity and maintain quality craftsmanship.

Ultimately, the choice of a fabric making machine is not just a financial decision; it is a strategic move that can shape the trajectory of a business. As companies strive for innovation and sustainability in their production processes, the importance of making an informed choice in machinery cannot be overstated.

Understanding the Types of Fabric Making Machines Available

When selecting a fabric making machine, it's crucial to understand the different types available in the market to ensure the right fit for your business needs. Broadly categorized, these machines include weaving, knitting, and non-woven options.

Weaving machines are designed for creating fabric by interlacing threads. They come in various configurations, such as automatic and semi-automatic looms, each offering different levels of production efficiency and versatility for diverse fabric types. This makes them suitable for businesses targeting high-output production of woven textiles.

On the other hand, knitting machines produce fabric by interlocking yarns, ideal for soft and stretchable materials like jersey and fleece. These machines also vary widely, from flat bed to circular knitting machines, meeting the demands of various textile applications.

Additionally, non-woven fabric machines manufacture materials by bonding fibers together through methods such as heat, chemical, or mechanical processes. This allows for the creation of specialized fabrics used in applications ranging from hygiene products to industrial textiles. Understanding these distinctions not only aids in making informed decisions but also positions your business to leverage the right technology for its specific fabric production requirements.

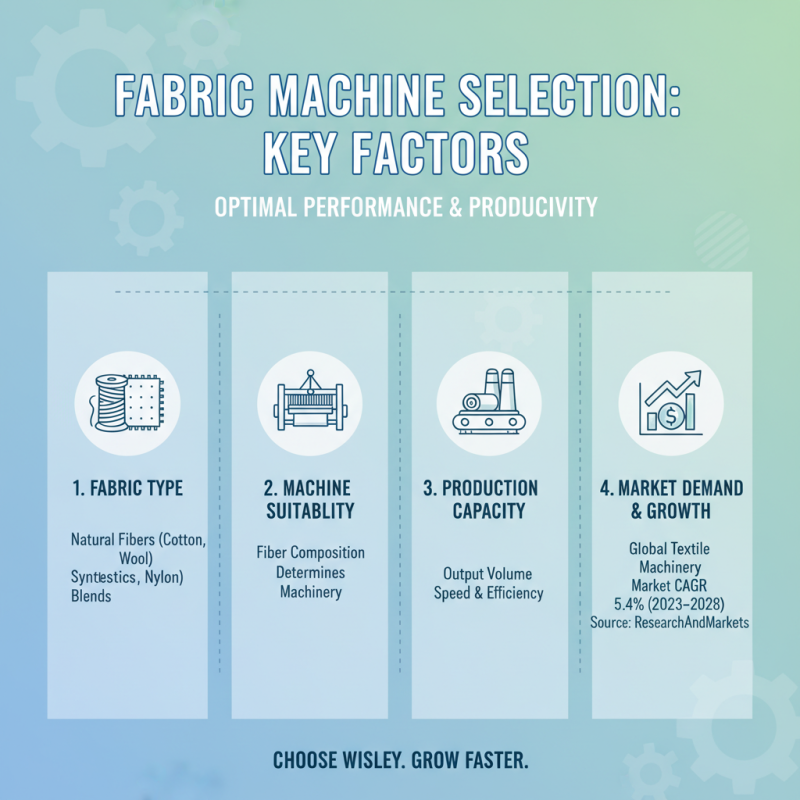

Factors to Consider When Selecting a Fabric Making Machine

When selecting a fabric making machine, several critical factors must be taken into account to ensure optimal performance and productivity. One of the foremost considerations is the type of fabric you aim to produce. The fabric composition—be it natural fibers, synthetics, or blends—will dictate the kind of machinery suitable for your operations. According to a report by ResearchAndMarkets, the global textile machinery market is projected to grow at a compound annual growth rate (CAGR) of 5.4% from 2023 to 2028, indicating the increasing demand for advanced textile machines tailored for specific fabric types.

Another vital aspect is the production capacity of the machine. Businesses need to evaluate their anticipated output levels to avoid over- or under-investing in machinery. For instance, a machine with a higher throughput may reduce per-unit production costs but could also require a higher initial investment. Data from the International Textile Machinery Association emphasizes that efficiencies in production can lead to a 20-30% reduction in costs over time, highlighting the importance of aligning machine capabilities with business growth objectives.

Lastly, automation features are becoming increasingly significant in the fabric production process. Machines equipped with smart technology can enhance efficiency, reduce labor costs, and improve product quality. A study published by the World Textile Information Network indicates that automating fabric making processes can boost productivity by up to 40%, making it a crucial consideration for businesses aiming to remain competitive in a rapidly evolving market.

The Impact of Technology on Fabric Production Efficiency

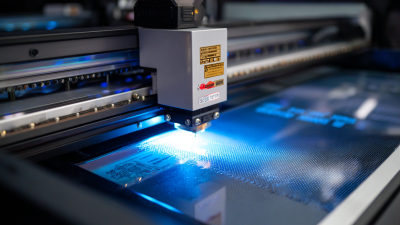

The impact of technology on fabric production efficiency is profound, as advancements in machinery and software have transformed traditional processes. Modern fabric-making machines are equipped with features that enhance precision, reduce waste, and increase output. For instance, automated cutting and sewing techniques minimize human error and significantly speed up production times. By leveraging technology, businesses can meet market demands more efficiently, providing high-quality products to consumers while maintaining competitive pricing.

Tips for businesses looking to optimize their fabric production include investing in training for staff to effectively use new technologies. This ensures that the team is fully equipped to harness the capabilities of modern machines. Additionally, regularly maintaining equipment can prevent costly downtimes and ensure that production remains seamless. It's also advisable to stay updated on emerging technologies in the industry, as innovations can lead to further improvements in efficiency and quality.

Another essential factor is data analytics, which can help in understanding production workflows and identifying bottlenecks. By analyzing performance metrics, businesses can make informed decisions about machinery upgrades and process adjustments. This strategic approach to technology management not only enhances production efficiency but also positions a company to adapt rapidly to changing market trends.

Why Choosing the Right Fabric Making Machine is Essential for Your Business Success - The Impact of Technology on Fabric Production Efficiency

| Machine Type | Production Speed (meters/hour) | Energy Consumption (kWh) | Fabric Types | Maintenance Frequency (months) |

|---|---|---|---|---|

| Weaving Machine | 300 | 5 | Cotton, Polyester | 12 |

| Knitting Machine | 250 | 4 | Wool, Acrylic | 10 |

| Printing Machine | 150 | 6 | Silk, Synthetic | 8 |

| Finishing Machine | 200 | 3 | Denim, Linen | 6 |

| Fusion Machine | 350 | 7 | Technical Fabrics | 15 |

Cost-Benefit Analysis of Different Fabric Making Machines

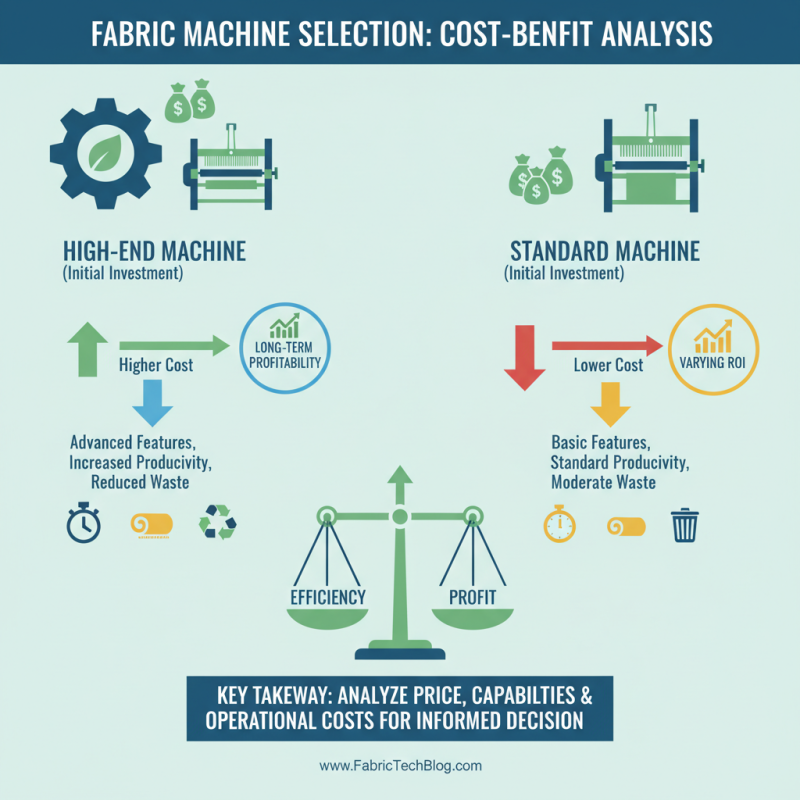

When it comes to fabric production, the choice of a fabric making machine can significantly impact the overall efficiency and profitability of a business. Conducting a thorough cost-benefit analysis is essential to make an informed decision. Various machines on the market possess different price points, capabilities, and operational costs, which can lead to varying returns on investment. For example, while a high-end machine may require a larger initial capital investment, it could offer advanced features that increase productivity and reduce waste in the long run.

In contrast, budget-friendly machines may present lower upfront costs but could potentially lead to higher operational expenses due to increased maintenance needs or lower output rates. Moreover, evaluating factors such as energy consumption, labor requirements, and the types of fabrics produced is crucial. By understanding these cost dynamics, businesses can better align their equipment choices with their production needs and financial goals, ultimately leading to improved efficiency and enhanced profitability in the highly competitive fabric industry.

Maintaining Your Fabric Making Machine for Optimal Performance

Maintaining your fabric making machine is crucial for ensuring optimal performance and longevity. Regular upkeep not only prevents unexpected breakdowns but also enhances the quality of the fabric produced. It is essential to establish a maintenance schedule that includes routine inspections, cleaning, and lubrication of moving parts. This proactive approach will help identify potential issues before they escalate, thereby reducing downtime and repair costs.

In addition to routine maintenance, it is important to train staff on the proper use and care of the machine. Providing comprehensive training can minimize user errors that lead to wear and tear. Moreover, keeping detailed records of maintenance activities can help track the machine’s performance and identify patterns that require attention. By investing time and resources into proper maintenance, businesses can achieve consistent quality in their fabric and ensure their production processes run smoothly.

Impact of Fabric Making Machine Efficiency on Business Performance

Related Posts

-

What is a Fabric Recycling Machine and How Does It Benefit the Environment

-

Top Fabric Coating Machines of 2025: Key Features and Buying Guide

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

How to Choose the Best Fabric Laser Cutting Machine in 2025

-

Top 10 Tips for Choosing the Right Fabric Printing Machine for Your Business