Top Fabric Making Machine Innovations Transforming the Textile Industry?

The textile industry is undergoing significant transformation, driven by innovative fabric making machines. These machines revolutionize production methods and enhance efficiency. They cater to the ever-evolving demands of fashion, sustainability, and technology.

In recent years, advancements have introduced automation, smart technology, and eco-friendly materials in fabric making. These innovations help manufacturers produce high-quality textiles with reduced waste. However, not all companies adapt quickly. This delay can impact competitiveness in a fast-paced market.

The integration of data analytics and artificial intelligence into fabric making machines is a double-edged sword. While it promises increased precision, it also raises questions about job displacement. As the industry moves forward, balancing innovation with social responsibility will be crucial for sustainable growth.

Emerging Technologies in Fabric Production Machines

Emerging technologies in fabric production are reshaping the textile industry. Traditional processes often lack efficiency, leading to significant waste. According to industry reports, approximately 15% of raw materials end up as waste in conventional fabric-making methods. New advancements aim to reduce this number.

One significant innovation is the use of 3D knitting technology. This allows for producing complex designs with less material. Some studies suggest that 3D printing in textiles can cut material waste by up to 40%. However, the technology is still expensive and not widely adopted. Many smaller manufacturers struggle to invest in these innovations.

Automation is another growing trend. Automated fabric cutting machines reduce labor costs and time. A report by the textile machinery association indicates that automation can boost production efficiency by 30%. Yet, this shift may lead to job losses, raising concerns about workforce displacement. Balancing technology and human resources remains a challenge in the evolving landscape of textile manufacturing.

Automation and Robotics in Textile Manufacturing Processes

Automation and robotics are reshaping the textile manufacturing landscape. According to recent industry reports, automation can boost production efficiency by up to 30%. This advancement significantly reduces labor costs and minimizes human error. Robots now handle tasks like cutting, sewing, and even quality inspection. These machines work tirelessly, ensuring consistent output without fatigue.

However, the transition to automated systems isn't without challenges. Many textile manufacturers face high initial costs for integration. Compatibility with existing systems is often an issue. Moreover, there’s a gap in skilled labor to operate these advanced machines. About 70% of companies report difficulty in finding workers trained in robotics. This skills mismatch highlights the need for further training and adaptation.

Yet, the push for automation is driven by market demands. Consumers seek faster production times and higher-quality textiles. Innovations in robotics enable manufacturers to meet these expectations. For instance, systems now offer real-time data analytics for inventory management. This capability allows for better decision-making. But reliance on technology raises concerns about job security. The industry must navigate this delicate balance between efficiency and employment.

Top Fabric Making Machine Innovations Transforming the Textile Industry

Sustainable Innovations in Fabric Making Equipment

The textile industry is undergoing a significant transformation. Sustainable innovations in fabric making equipment are at the forefront of this change. Many companies now use eco-friendly materials. This shift helps reduce waste and promotes a more circular economy.

Some machines are designed to minimize water usage. Traditional methods often waste large amounts of water. New technologies are addressing this challenge by recycling water effectively. Moreover, energy-efficient machines are emerging. They consume less power and lower greenhouse gas emissions.

However, not all innovations are perfect. Some new machines require high initial investments. Additionally, training workers to operate these complex systems can be challenging. There is also a risk that smaller manufacturers may struggle to adopt these changes. The journey towards sustainability is ongoing, and there is still much to improve.

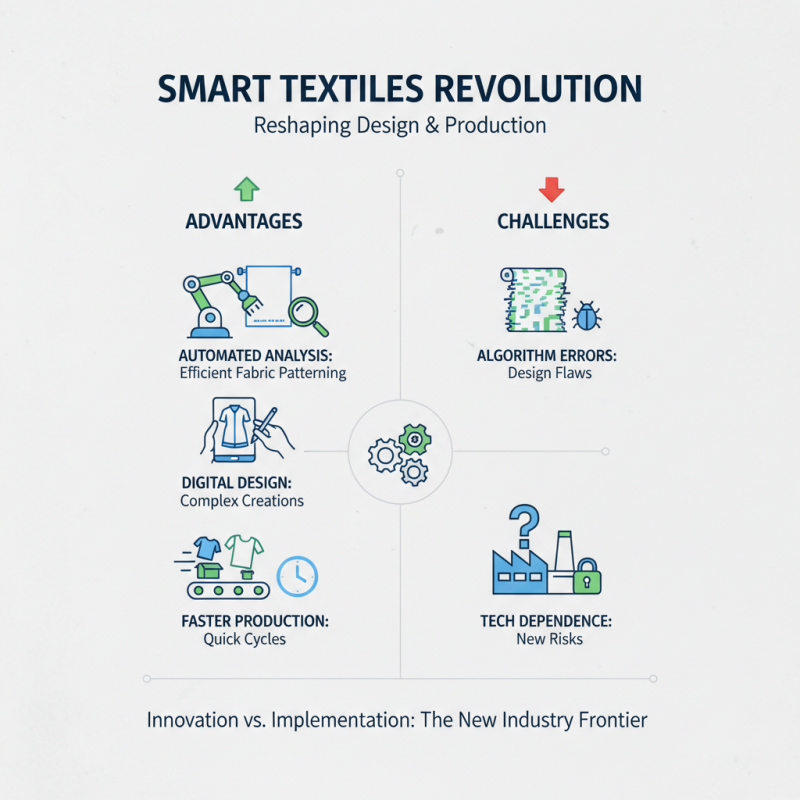

Impact of Smart Technology on Textile Design and Production

The integration of smart technology into textile design and production is reshaping the industry. Automated machines now analyze fabric patterns more efficiently. Designers can experiment with intricate designs using digital tools. This transformation leads to faster production cycles. However, reliance on technology poses challenges. Errors in algorithms can lead to design flaws.

Smart devices also enhance sustainability efforts. They monitor resource usage in real-time. This capability helps reduce waste and lower costs. Yet, the shift to smart technology requires training. Workers need to adapt to new systems. It's not always easy to find the right balance between innovation and traditional methods.

Collaboration between designers and engineers is crucial. Each party must understand the implications of technology. Communication can sometimes be a barrier. Misunderstandings may lead to delays in production. The push for innovation is exciting, but it invites scrutiny. Not every new technology will fit seamlessly into existing workflows. Reflection on each change is necessary for success.

Future Trends in Fabric Making Machines and Industry Adaptation

The textile industry is on the brink of transformation. New fabric making machines are emerging, equipped with advanced technologies. Automation plays a significant role in enhancing production efficiency. These machines use smart algorithms to optimize fabric quality and reduce waste. However, the integration of such innovations can be challenging for many manufacturers.

Sustainability has become a vital trend in fabric production. Machines designed for recycling materials are gaining traction. These technologies can convert waste fibers back into usable fabrics. Yet, manufacturers face hurdles in implementing these systems effectively. The initial investment can be daunting, and the learning curve steep. As the industry shifts, traditional practices may need reevaluation.

Consumer demand is evolving rapidly. There is a push for more personalized fabrics in fashion. Some machines now allow quicker customization. This adaptability means that factories might need to change their operations frequently. But, not all businesses can keep pace with these shifts. It’s a complicated balancing act between innovation and tradition, requiring thoughtful strategies.

Related Posts

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

What is a Fabric Weaving Machine and How Does it Work in Textile Production

-

Top 10 Best Weaving Machines for Efficient Textile Production

-

Top 10 Tips for Using Ultrasonic Fabric Cutting Machines Effectively

-

Why Choose an Industrial Fabric Printing Machine for Your Business?

-

Revolutionize Your Business with Advanced Industrial Fabric Printing Machines: Trends and Tips for Success