Top 10 Fabric Printing Machines for High Quality Custom Designs

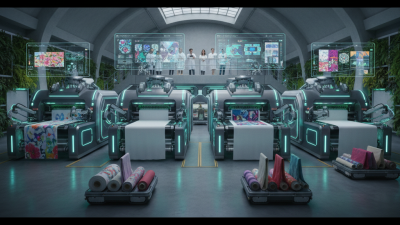

In the ever-evolving world of textile design, the importance of high-quality fabric printing machines cannot be overstated. As Alex Turner, a renowned expert in the fabric printing machine industry, eloquently stated, “The right machine can transform creative visions into vivid reality, turning fabric into a canvas of endless possibilities.” This quote encapsulates the essence of what custom designs demand in today's competitive market—precision, quality, and versatility.

In recent years, the advancement of technology has significantly impacted the fabric printing landscape, leading to innovations that empower designers and manufacturers alike. With a plethora of options available, selecting the ideal fabric printing machine becomes crucial for achieving stunning results that meet the diverse needs of clients. This article will explore the top 10 fabric printing machines that stand out for their performance, reliability, and ability to deliver high-quality custom designs, providing valuable insights for anyone looking to elevate their fabric printing capabilities.

Overview of Fabric Printing Technology and Its Applications

Fabric printing technology has revolutionized the textile industry, enabling designers to create intricate and personalized patterns on various fabrics. This process can be broadly categorized into several techniques, including screen printing, dye sublimation, and digital printing. Each method offers distinct advantages and is chosen based on the desired quality, texture, and usage of the final product. For instance, screen printing is ideal for large volume runs due to its efficiency and cost-effectiveness, while digital printing allows for greater flexibility and detailed designs, making it suitable for custom orders and small batches.

The applications of fabric printing extend beyond fashion into numerous industries, including home décor, automotive upholstery, and promotional materials. Designers are increasingly leveraging digital fabric printing to produce custom textiles such as unique wall coverings, bespoke drapes, and personalized clothing items. This versatility not only enhances creativity but also fosters sustainable practices, as it enables on-demand production that reduces waste. As technology continues to evolve, the potential for innovative applications in fabric printing seems limitless, encouraging a blend of artistry and functionality that meets the diverse needs of consumers.

Top 10 Fabric Printing Machines for High Quality Custom Designs

| Machine Type | Print Technology | Max Print Width | Speed (m²/h) | Applications |

|---|---|---|---|---|

| Direct to Fabric | Inkjet | 1.8 m | 50 | Apparel, Home Décor |

| Sublimation Printer | Dye Sublimation | 3.2 m | 70 | Sportswear, Banners |

| Flatbed Printer | UV Inkjet | 2.5 m | 40 | Signage, Exhibits |

| Roll-to-Roll Printer | Eco-Solvent | 3.2 m | 60 | Banners, Flags |

| Industrial Printer | Digital Textile | 2.0 m | 80 | Fashion, Upholstery |

| Textile Transfer | Heat Transfer | 1.5 m | 30 | Custom Orders, Products |

| Hybrid Printer | Mixed Technology | 2.2 m | 55 | Creative Textiles, Art |

| Computerized Embroidery Machine | Embroidery | Varies | 20 | Embellishments, Logos |

| Flatbed Cutter | Cutting Technology | 1.4 m | N/A | Pattern Making, Sampling |

| Laser Cutter | Laser Technology | 1.5 m | N/A | Fine Detail Work, Cutting |

Key Features to Consider in Fabric Printing Machines

When selecting a fabric printing machine for high-quality custom designs, several key features should be carefully considered. First and foremost is the printing technology employed by the machine. Options like dye-sublimation, direct-to-garment (DTG), and UV printing each offer unique advantages depending on the fabric type and design complexity. Understanding how each technology interacts with various materials ensures that the printed designs maintain vibrancy and durability over time.

Another crucial aspect is the machine's print resolution and speed. Higher resolution settings are essential for producing intricate designs and fine details, while adequate printing speed is vital for meeting production deadlines without compromising quality. Additionally, consider the machine’s compatibility with different fabric types, as versatility can enhance creativity and expand your design possibilities. Lastly, built-in features such as software integration for design editing and color management tools can significantly streamline the printing process and improve overall output.

Top 10 Fabric Printing Machines for Quality Custom Designs

When it comes to creating quality custom designs, the choice of fabric printing machines plays a crucial role in ensuring high standards of print quality and durability. According to a report by Smithers Pira, the global digital textile printing market is expected to reach $3.9 billion by 2024, driven by advancements in printing technologies and a growing demand for short-run production. This evolution in technology has significantly increased the precision and vibrancy of fabric prints, making it essential for businesses to invest in top-tier machines that can produce intricate designs with consistency.

Among the leading contenders in the market, machines such as the Epson SureColor F-series and the Mimaki JV300 series have garnered attention for their performance. These machines not only offer superior ink quality but also deliver a wider color gamut, enabling designers to produce stunning and detailed prints. By employing these advanced fabric printing machines, businesses can meet the rising consumer expectations for custom textiles, which research indicates has been a crucial factor in maintaining competitive advantage within the textile industry. With capabilities for high-speed production and eco-friendly printing processes, investing in the right fabric printing technology is not just an option but a necessity for those aiming to excel in quality custom designs.

Comparative Analysis of Leading Fabric Printing Brands

The fabric printing industry has seen significant advancements over recent years, making it essential for businesses to choose the right machine for high-quality custom designs. According to a report by Smithers Pira, the global digital textile printing market is expected to grow at a CAGR of 20.1% from 2021 to 2026, underscoring the rising demand for high-resolution fabric printing solutions. Brands like Epson and Mimaki have emerged as leaders by offering state-of-the-art technologies that cater to various textile applications, including fashion, home decor, and industrial use.

A comparative analysis of leading fabric printing brands reveals distinct features that set them apart. Epson, for instance, utilizes PrecisionCore technology, which enables high-speed printing with remarkable color accuracy, making it ideal for detailed custom designs. On the other hand, Mimaki's innovative UV and dye-sublimation printers are designed for versatility and sustainability, catering to eco-conscious consumers. According to data from the International Digital Textile Printing Conference, brands adopting eco-friendly practices are witnessing a market share increase of approximately 15%, indicating a significant shift towards sustainable production methods in the fabric printing sector.

Tips for Maintaining and Optimizing Fabric Printing Machines

Maintaining and optimizing fabric printing machines is crucial for achieving high-quality custom designs and extending the lifespan of your equipment. According to the latest industry reports, regular maintenance can increase the efficiency of printing machines by up to 30%. This involves routine checks on the ink delivery system, print heads, and cleaning of the nozzles to prevent clogs, which can disrupt production and affect print quality.

In addition to regular maintenance, optimizing settings based on fabric type can significantly impact the final output. For instance, adjusting the print speed and pressure settings according to the material's characteristics can lead to improved color accuracy and detail. A study from the Fabric Printing Association revealed that machines calibrated to suit specific fabrics often yield a 20-25% increase in vibrancy and clarity of designs. Furthermore, investing in advanced software solutions for color matching and design pre-visualization can streamline the printing process and reduce errors, ultimately enhancing productivity and client satisfaction.

Top 10 Fabric Printing Machines - Performance Comparison

Related Posts

-

Top 10 Digital Textile Printing Machines to Enhance Your Printing Business

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production

-

How to Choose the Best Fabric Laser Cutting Machine for Your Business

-

Top 5 Benefits of Using Industrial Fabric Laser Cutting Machines for Your Business