What is a Fabric Weaving Machine and How Does it Work in Textile Production

The textile industry is a vital component of the global economy, with a market value estimated to reach 1.23 trillion USD by 2025, driven by the increasing demand for various fabric products. Central to this production process is the fabric weaving machine, which plays an essential role in transforming raw materials into finished textiles. This machine operates by interlacing threads at right angles to create complex patterns and durable materials, fulfilling the unique requirements of fashion, home furnishings, and industrial applications.

In recent years, advancements in technology have significantly enhanced the efficiency and precision of fabric weaving machines. With capabilities such as automated control systems and sophisticated design software, these machines can produce intricate fabric designs while minimizing waste. Reports suggest that the introduction of computerized weaving machines has led to an increase in production speed by up to 50%, showcasing their impact on the overall productivity of textile manufacturing. As the demand for high-quality, customized fabrics continues to rise, understanding the mechanics and innovations of fabric weaving machines becomes crucial for industry stakeholders to remain competitive and sustainable in this dynamic market.

What is a Fabric Weaving Machine?

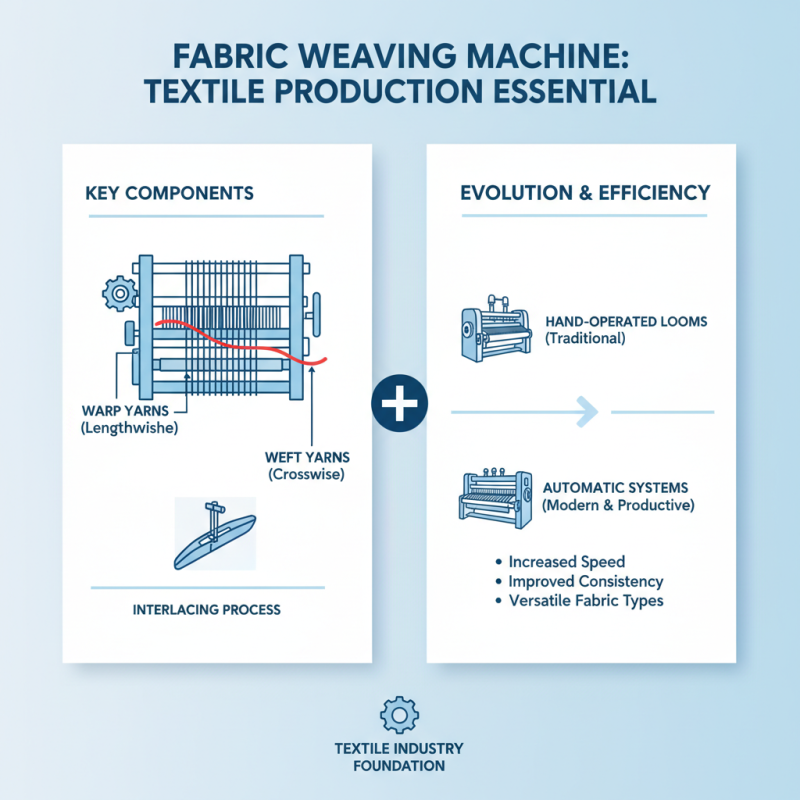

A fabric weaving machine is an essential piece of equipment in the textile industry, designed to interlace threads to produce various types of fabrics. These machines utilize two primary sets of yarns: the warp, which runs lengthwise, and the weft, which is woven across the width. The precision and efficiency of weaving machines have evolved significantly over time, transitioning from hand-operated looms to advanced automatic systems that enhance productivity and consistency.

The basic operation of a weaving machine begins with the setup of the warp threads, which are arranged on a beam at the back of the machine. As the loom operates, the shuttle carrying the weft yarn is traversed across the warp threads, inserting the weft into the desired pattern. The process is repeated in a rhythmic cycle, with the machine adjusting to create different weave structures such as plain, twill, or satin. Modern weaving machines are equipped with computerized controls that allow for intricate designs and faster production speeds, ultimately revolutionizing fabric manufacturing and reducing labor costs while maintaining high-quality outputs.

Key Components of Fabric Weaving Machines

Fabric weaving machines are essential equipment in the textile production industry, playing a critical role in transforming raw fibers into woven fabrics. Understanding the key components of these machines is vital for grasping their functionality and effectiveness in production. The primary components include the warp and weft yarns, shedding mechanisms, beat-up mechanisms, and take-up devices. Each of these parts works in synchrony to create various fabric types, ranging from simple plain weaves to complex patterns.

The warp yarns are the longitudinal threads held taut on the loom, while the weft yarns are inserted crosswise. Shedding mechanisms, such as Jacquard or Dobby, create a gap between the warp threads, allowing the weft to pass through. Industry reports indicate that the global market for weaving machines is projected to grow significantly, with a CAGR of about 5.2% from 2023 to 2030, driven by advancements in technology and increasing demand for high-quality textiles. Additionally, beat-up mechanisms, which push the newly inserted weft into place, are essential for achieving desired fabric density and texture.

Furthermore, the take-up device winds the finished fabric onto a roller, ready for the next phase in textile processing. According to a report by Technavio, innovations in automation and smart technology have increased the efficiency of weaving machines, reducing labor costs and improving production speeds by as much as 30%. As manufacturers continue to invest in modern weaving machines, these key components remain crucial for meeting the evolving demands of the textile market.

Types of Weaving Machines and Their Applications

Weaving machines are essential tools in textile production, and they come in various types, each serving distinct purposes according to the fabric requirements. The most common types include shuttle looms, rapier looms, air jet looms, and flat-bed looms. Shuttle looms operate by using a shuttle to carry the weft yarn across the warp threads, making them ideal for producing sturdy fabrics like denim. They are well-suited for traditional weaving techniques and are commonly used for both fashion and home textiles, thanks to their reliability and versatility.

On the other hand, rapier and air jet looms are known for their high-speed capabilities, making them suitable for producing lightweight and fine fabrics. Rapier looms utilize a rapier to insert the weft yarn, allowing for a wide variety of yarn types and a smooth weaving process. Air jet looms, however, leverage bursts of air to propel the weft yarn, resulting in remarkable speed and efficiency. These machines are particularly favored in the mass production of textiles, as they facilitate quick changeovers and can handle complex patterns. Each type of weaving machine plays a vital role in the efficiency and output quality of textile manufacturing, catering to diverse market needs.

The Weaving Process: Step-by-Step Overview

The weaving process is a critical component of textile production, involving a systematic series of steps that transform yarn into fabric. It begins with the preparation of the warp and weft threads. The warp is the set of longitudinal threads that are stretched on the loom, while the weft threads are woven across the warp. According to the International Textile Manufacturers Federation (ITMF), approximately 60% of textile production involves weaving, highlighting its significance in the industry.

Once the threads are prepared, they are laced on a weaving machine, where the actual weaving takes place. The loom raises and lowers the warp threads to create a shed, which allows the weft to be inserted. This process requires precision, as any deviation can lead to defects in the fabric. Reports indicate that advancements in technology, such as the use of automatic looms, have improved production efficiency by up to 30%, enabling manufacturers to produce more intricate designs at a faster rate. The weaving process continues with the beating up of the weft to ensure tightness and consistency, followed by the finishing processes that include washing, dyeing, and setting the final texture of the fabric.

As the final stage approaches, quality control measures are critical. Testing for tensile strength and durability is often performed, conforming to the standards defined by organizations like the American Society for Testing and Materials (ASTM). This ensures that the fabric not only meets aesthetic standards but also performs well in practical applications, reinforcing the importance of a meticulous weaving process in textile production.

Fabric Production Stages

Benefits of Fabric Weaving Machines in Textile Production

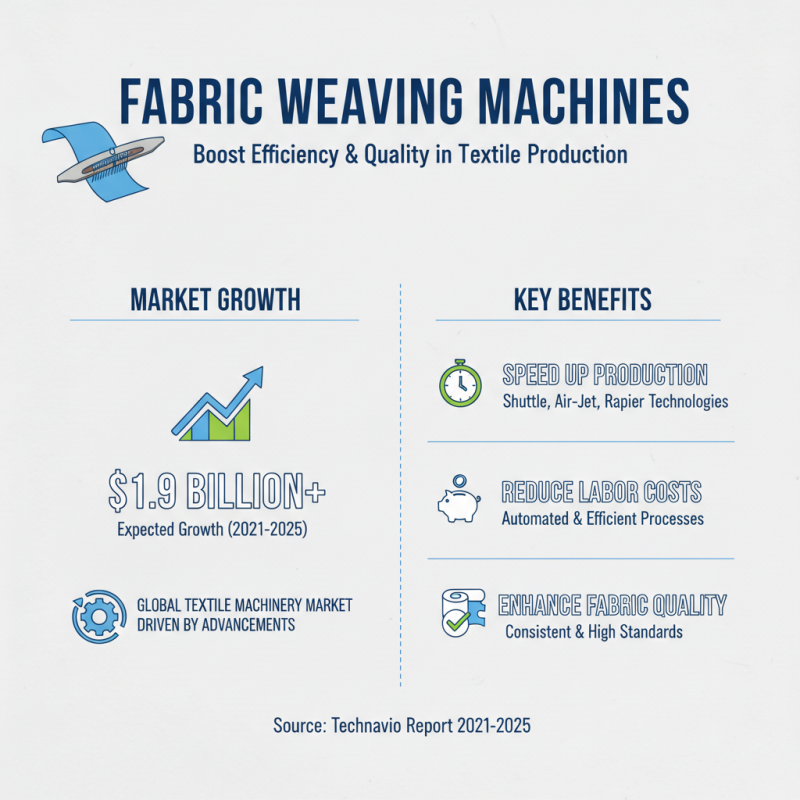

Fabric weaving machines play a crucial role in textile production, delivering numerous benefits that enhance efficiency and quality. According to a report by Technavio, the global textile machinery market is expected to grow by over $1.9 billion from 2021 to 2025, driven by advancements in textile manufacturing technologies, particularly weaving machines. These machines, which utilize processes like shuttle weaving, air-jet, or rapier technology, significantly improve production speeds and reduce labor costs while maintaining high standards of fabric quality.

The benefits of fabric weaving machines extend beyond mere efficiency. For instance, modern weaving machines often allow for greater precision and flexibility in design, enabling manufacturers to produce complex patterns and textures that cater to diverse consumer preferences. A study from MarketsandMarkets indicates that the global demand for technical textiles, which require specialized weaving techniques, is predicted to grow at a compound annual growth rate (CAGR) of 4.8% from 2020 to 2025. This illustrates how weaving machines not only support traditional textile production but also cater to emerging markets, thus providing substantial competitive advantages for manufacturers who invest in advanced technologies.

Related Posts

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

Top 5 Benefits of Using Industrial Fabric Laser Cutting Machines for Your Business

-

How to Effectively Use Textile Waste Recycling Machine for Sustainable Practices

-

Top 10 Fabric Printing Machines for High Quality Custom Designs

-

How to Choose the Best Fabric Laser Cutting Machine in 2025

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production