2026 How to Operate an Ultrasonic Fabric Cutting Machine Effectively?

Operating an ultrasonic fabric cutting machine requires precision and understanding. This technology utilizes high-frequency sound waves to cut fabrics smoothly. Many industries benefit from this technique, such as fashion and textiles. However, it's not as straightforward as it seems.

Users often face challenges when adjusting settings on the ultrasonic fabric cutting machine. Proper calibration is essential for achieving clean cuts. Inexperience can lead to fabric damage or inefficient cutting patterns. Observing the machine's performance helps identify areas for improvement.

Moreover, mastering the ultrasonic fabric cutting machine involves practice and reflection. Familiarizing yourself with different fabrics is key. Each type behaves differently under ultrasonic cutting. This variability can impact final product quality. Take time to analyze your work and learn from mistakes.

Understanding the Basics of Ultrasonic Fabric Cutting Technology

Ultrasonic fabric cutting technology is a game-changer in the textile industry. It uses high-frequency sound waves to create friction. This friction generates heat, allowing fabrics to be cut cleanly without fraying. According to a report by Technavio, the ultrasonic cutting machine market is expected to grow by 32% from 2021 to 2025. This growth highlights the increasing adoption of this technology.

One key advantage of ultrasonic cutting is its precision. The process can easily cut intricate designs, reducing waste. However, operators must understand the limitations. Not all fabrics respond similarly to ultrasonic cuts. Some thicker materials may require additional testing. Reports show a 15% error rate in initial setups. This can lead to frustration and wasted resources.

Proper training and setup are essential for effective operation. Each fabric type may require adjustments in frequency and amplitude. The impact of operator experience cannot be overstated. Poor operation can compromise the entire cutting process. Invest time in understanding material properties and machine capabilities. Adapting to different challenges will yield better results and reduce costs over time.

2026 How to Operate an Ultrasonic Fabric Cutting Machine Effectively? - Understanding the Basics of Ultrasonic Fabric Cutting Technology

| Aspect | Description | Importance | Recommendations |

|---|---|---|---|

| Machine Setup | Properly configure the ultrasonic cutting machine settings based on fabric type. | Ensures optimal cutting efficiency and quality. | Refer to machine manual for recommended settings. |

| Fabric Type | Different fabrics behave differently under ultrasonic cutting. | Important for achieving clean cuts without fraying. | Test cuts on sample pieces of fabric first. |

| Blade Maintenance | Regular maintenance of ultrasonic blades is critical. | Maintains cutting quality and extends machine lifespan. | Schedule regular inspections and cleaning. |

| Operator Training | Trained operators can maximize the use of ultrasonic cutting technology. | Increases safety and improves overall productivity. | Provide thorough training sessions for all operators. |

| Quality Control | Implementing regular quality checks during production. | Ensures final product quality and reduces waste. | Set up checkpoints to monitor cut quality consistently. |

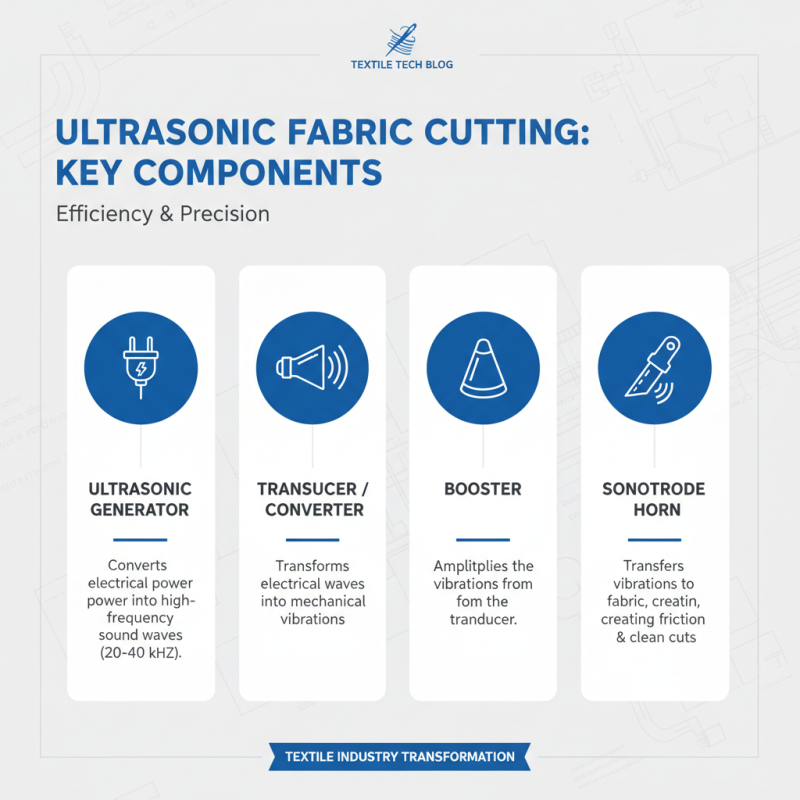

Key Components of an Ultrasonic Fabric Cutting Machine

Ultrasonic fabric cutting machines have transformed the textile industry. Their efficiency and precision largely stem from key components. Understanding these elements is vital for effective operation.

One essential component is the ultrasonic transducer. This device converts electrical energy into high-frequency sound waves. It generates the vibration necessary for cutting. The quality of the transducer directly affects cutting performance. Not all transducers are created equal, and some may wear out faster than others.

Next is the ultrasonic knife, which interacts with the fabric. This knife needs to be well-maintained for optimal performance. Dull knives can lead to frayed edges. They require regular checks and replacements to avoid issues. The operator should know when to change them to maintain cutting quality. Ignoring this can lead to wasted materials and time.

Lastly, the generator plays a crucial role. It provides the power for the entire system. An unreliable generator can disrupt workflow and create inconsistencies in cutting. Operators must understand how to adjust power settings based on the material being cut. Failure to do so may cause undesirable results and inefficiencies.

Step-by-Step Guide to Setting Up the Ultrasonic Cutting Machine

Setting up an ultrasonic cutting machine requires attention to detail. Begin by ensuring that the machine is placed on a stable, level surface. This stability prevents vibrations that can affect cutting accuracy. Consider the workspace layout. An organized area enhances efficiency and safety. Maintain clear access to the machine controls for quick adjustments.

Next, connect the power supply. Be cautious with voltage settings to avoid overheating. According to industry studies, incorrect voltage can lead to a 15% increase in machine failures. After powering on, check the ultrasonic generator settings. These settings influence fabric consistency. A report from the Textile Machinery Association states that precise settings can boost cutting efficiency by up to 30%.

It’s crucial to select the right cutting tool for your fabric type. Different materials respond uniquely to ultrasonic cutting. For example, delicate fabrics may require lower power settings. Miscalculating these settings can result in frayed edges or uneven cuts. Always test on scrap material before proceeding with production. This testing phase allows for adjustments, ensuring the optimal cutting performance.

Effectiveness of Ultrasonic Cutting Machines - Overview

Best Practices for Operating the Ultrasonic Fabric Cutter Efficiently

Operating an ultrasonic fabric cutting machine requires precision. The efficiency of the machine depends on various factors, including the settings and the operator’s skill level. According to industry reports, improper settings can lead to excessive material waste, with an average of 15% of fabric being unusable due to flawed cuts. Keeping the machine well-maintained can significantly reduce such losses.

One effective practice is to regularly calibrate the ultrasonic cutting mechanism. Regular checks ensure that the frequency remains stable. Unstable frequency may lead to inconsistent cuts. Additionally, understanding the type of fabric being cut is crucial. For instance, heavier materials may require different cutting speeds. Operators should also be aware of the ambient conditions; temperature and humidity can affect cutting performance.

Proper training for operators is essential, yet often overlooked. A survey indicated that 30% of operators reported feeling undertrained. This lack of training can lead to mistakes, ultimately affecting production quality. Creating a detailed operating manual tailored to your machine can mitigate this issue. Operators must practice and refine their skills. Experience is key to achieving optimal results and minimizing errors.

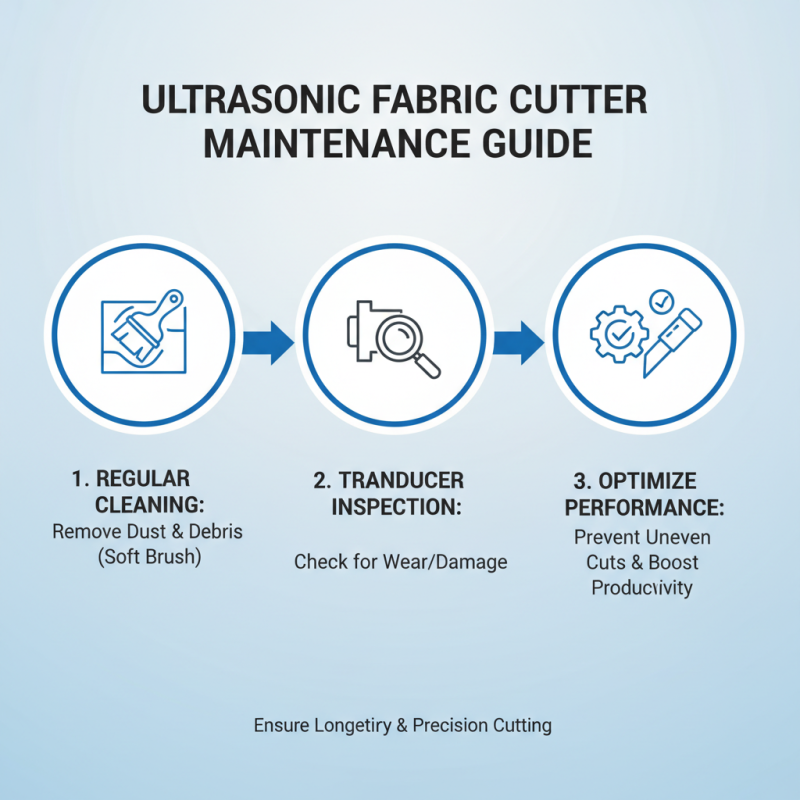

Maintenance Tips for Longevity of Ultrasonic Fabric Cutting Equipment

Maintaining an ultrasonic fabric cutting machine is crucial for its longevity. Regular cleaning is essential. Dust and fabric debris can accumulate, impacting performance. Use a soft brush to remove particles from the cutting area. Inspect the transducer regularly for any signs of wear. A damaged transducer can lead to uneven cuts and affect productivity.

Another tip involves proper storage when the machine is not in use. Keep it in a dry, dust-free environment. Humidity can damage components, leading to costly repairs. Additionally, ensure that the cutting blade is sharpened and checked frequently. A dull blade can result in frayed edges and wasted fabric.

Don’t overlook routine inspections of electrical connections. Loose connections can cause intermittent issues. Take the time to secure all wiring before operational shifts. Training staff on proper machine handling also plays a role. Misuse can lead to mechanical problems, which might require professional intervention. Regular attention to these details ensures consistent performance from your ultrasonic fabric cutting equipment.

Related Posts

-

Top 10 Digital Textile Printing Machines to Enhance Your Printing Business

-

What is a Fabric Weaving Machine and How Does it Work in Textile Production

-

How to Choose the Best Fabric Laser Cutting Machine in 2025

-

How to Choose the Right Industrial Weaving Machine for Your Needs?

-

Revolutionize Your Business with Advanced Industrial Fabric Printing Machines: Trends and Tips for Success

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!