Why Investing in Textile Machinery is Essential for Modern Manufacturing Success

In the ever-evolving landscape of modern manufacturing, investing in textile machinery is more crucial than ever for ensuring competitive success. The textile industry serves as a cornerstone of the global economy, and advancements in machinery play a pivotal role in enhancing productivity, efficiency, and sustainability. As market demands shift towards faster production cycles and higher quality standards, manufacturers must adapt by integrating cutting-edge textile machinery that not only streamlines operations but also meets the growing expectations of consumers.

Moreover, the right textile machinery can significantly reduce production costs and environmental impact, aligning with the increasing emphasis on sustainable practices within the industry. By making strategic investments in advanced machinery, manufacturers can harness innovative technologies that facilitate automation, reduce waste, and improve product quality. This not only positions companies to achieve greater operational efficiency but also establishes them as leaders in a competitive market.

In summary, the significance of investing in textile machinery cannot be overstated. As manufacturing practices continue to evolve, embracing advanced textile machinery is a critical step toward achieving long-term success and sustainability in the textile industry. Companies that prioritize these investments will be better equipped to navigate challenges, capitalize on opportunities, and ultimately thrive in a dynamic economic landscape.

Investing in Textile Machinery: A Strategic Move for Competitive Advantage

Investing in textile machinery is a strategic move that provides manufacturers with a significant competitive advantage in today's fast-evolving market. As industries become more focused on efficiency and sustainability, advanced textile machinery allows for automation and precision that traditional methods simply cannot match. This shift not only reduces labor costs but also minimizes waste, allowing manufacturers to optimize their production processes and lower overhead expenses.

Moreover, modern textile machinery incorporates smart technology such as IoT and data analytics, enabling real-time monitoring and predictive maintenance. This technological integration enhances productivity by reducing downtime and improving overall production quality. By investing in state-of-the-art equipment, manufacturers can not only meet the increasing demand for high-quality textile products but also adapt swiftly to changing consumer preferences and trends. In a landscape where adaptability is crucial, such investments empower companies to stay ahead of the competition and secure their position in the market.

Impact of Advanced Textile Machinery on Production Efficiency and Output

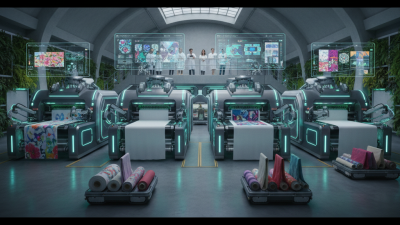

The integration of advanced textile machinery plays a pivotal role in enhancing production efficiency and output in modern manufacturing. These sophisticated machines streamline various processes, from spinning and weaving to dyeing and finishing, significantly reducing operational time and minimizing waste. By automating repetitive tasks and employing precise control mechanisms, modern textile machinery allows manufacturers to achieve higher accuracy and consistent quality in their products. This advancement not only optimizes resource utilization but also enables manufacturers to respond more swiftly to market demands.

Moreover, the implementation of cutting-edge technology in textile manufacturing encourages innovation and customization. Advanced machinery often features smart technology that can adapt to different production needs, allowing for shorter lead times and greater flexibility in design. This adaptability ensures that manufacturers can produce a diverse range of textiles efficiently, meeting the varying preferences of consumers. As a result, businesses can expand their product offerings while maintaining high standards of quality, ultimately contributing to increased competitiveness in a rapidly evolving market.

Impact of Advanced Textile Machinery on Production Efficiency

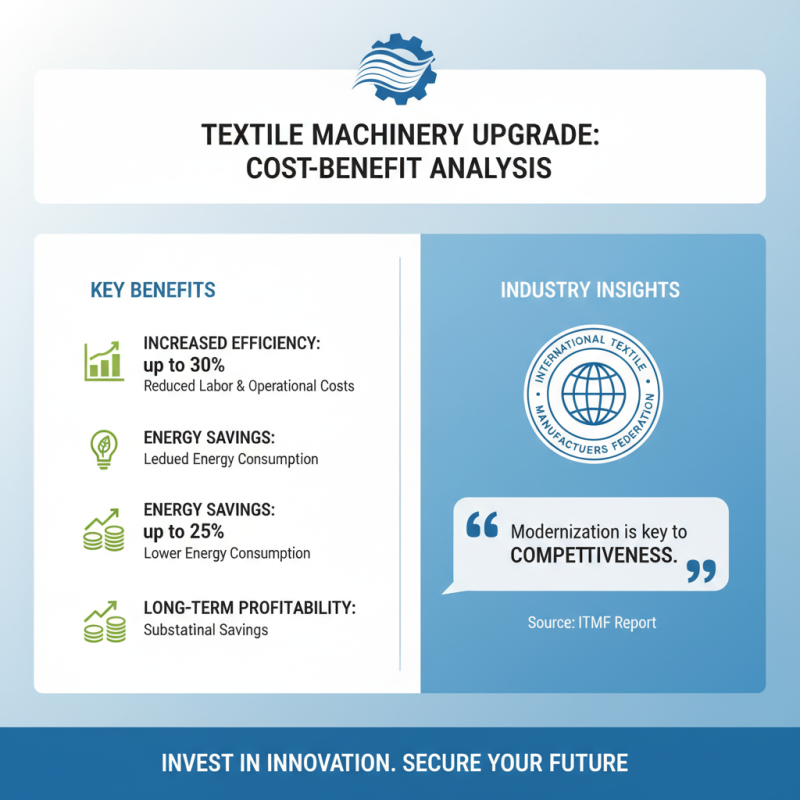

Cost-Benefit Analysis of Upgrading Textile Equipment in Manufacturing

Investing in textile machinery is a pivotal decision for manufacturers aiming to enhance productivity and maintain competitiveness in an ever-evolving market. A comprehensive cost-benefit analysis reveals that upgrading textile equipment can lead to substantial long-term savings and profitability. According to a recent report by the International Textile Manufacturers Federation, modernizing textiles machinery can increase efficiency by up to 30%, translating to significant reductions in labor and operational costs. Additionally, advanced equipment often comes with enhanced energy efficiency features, which can reduce energy consumption by as much as 25%—a critical factor considering the rising energy prices globally.

Furthermore, the initial capital investment in new machinery allows for the adoption of innovative production techniques, enabling manufacturers to respond swiftly to changing consumer demands and market trends. A study conducted by the Textile Industry Association highlighted that companies that invested in state-of-the-art machinery reported a 15% increase in product quality and a 10% reduction in waste. This not only improves profitability but also aligns with sustainable manufacturing practices, appealing to environmentally conscious consumers. The data strongly suggests that the up-front costs associated with upgrading textile equipment are outweighed by the long-term financial and operational benefits, reinforcing the necessity of investing in modern textile machinery for manufacturing success.

Innovations in Textile Machinery: Enhancing Quality and Sustainability

The textile industry is undergoing a transformative shift driven by technological innovations that enhance both quality and sustainability. The introduction of advanced textile machinery, such as automated weaving and knitting systems, has significantly improved production efficiency while ensuring higher precision in fabric creation. These innovations enable manufacturers to produce textiles that meet the increasing consumer demand for superior quality and durability, thus setting new industry standards.

Moreover, sustainability has become a pivotal concern in modern manufacturing. Innovative textile machinery is now designed with eco-friendly processes in mind, allowing for reduced water and energy consumption during production. Technologies such as digital printing and recycling systems enable manufacturers to minimize waste and promote the use of sustainable materials, aligning with global sustainability goals. By investing in such advanced machinery, textile manufacturers not only enhance their operational efficiency but also contribute to a greener economy, meeting the expectations of environmentally conscious consumers.

Market Trends: Growth Projections for the Textile Machinery Industry Through 2025

The textile machinery industry is poised for significant growth through 2025, driven by advancements in technology and increasing demands for efficiency in manufacturing processes. As consumer preferences evolve towards sustainable and high-quality products, manufacturers are compelled to invest in modern machinery that enhances productivity and reduces waste. Automation and digitalization are becoming integral parts of textile production, leading to a surge in demand for state-of-the-art equipment that can cater to these new trends.

Moreover, the expansion of the global textile market, particularly in developing regions, presents a vast opportunity for the textile machinery sector. Rising disposable incomes and the subsequent increase in consumer spending on textiles are fueling investments in machinery to meet production demands. It is expected that innovations in areas such as smart manufacturing and sustainable practices will further bolster growth, as companies aim to stay competitive by adopting cutting-edge technologies. Consequently, the textile machinery industry is not only a vital component of modern manufacturing but also a catalyst for sustainable growth in the broader textile market.

Why Investing in Textile Machinery is Essential for Modern Manufacturing Success - Market Trends: Growth Projections for the Textile Machinery Industry Through 2025

| Year | Market Size (Billion USD) | Growth Rate (%) | Key Innovations |

|---|---|---|---|

| 2021 | 23.5 | 5.2 | Automation and IoT Integration |

| 2022 | 24.6 | 4.7 | Sustainable Materials Technology |

| 2023 | 26.1 | 6.1 | Digital Fabric Printing |

| 2024 | 27.9 | 6.9 | AI-Powered Design Tools |

| 2025 | 29.6 | 6.2 | Smart Wearable Technology |

Related Posts

-

What is a Fabric Weaving Machine and How Does it Work in Textile Production

-

How to Effectively Use Textile Waste Recycling Machine for Sustainable Practices

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production

-

How to Choose the Best Fabric Laser Cutting Machine for Your Business

-

Top 10 Digital Textile Printing Machines to Enhance Your Printing Business