Top 10 Tips for Choosing the Right Fabric Printing Machine for Your Business

In the rapidly evolving world of textile production, the choice of a fabric printing machine is a crucial decision that can significantly impact the efficiency and quality of your business operations. According to a report by Smithers Pira, the global digital textile printing market is projected to reach $3.4 billion by 2024, driven by the increasing demand for customized and on-demand printing solutions. As businesses strive to stay competitive in this dynamic environment, selecting the right fabric printing machine has become more important than ever.

When navigating the myriad of options available in the market, it is essential to consider factors such as printing technology, production capacity, and the specific needs of your target market. Research indicates that 70% of businesses report improved profitability after investing in modern fabric printing equipment, highlighting the potential benefits of making an informed choice. This comprehensive guide will explore the top 10 tips for selecting the perfect fabric printing machine, helping you to make a decision that aligns with your business goals and customer demands.

Understanding Different Types of Fabric Printing Machines

When selecting a fabric printing machine for your business, it's essential to understand the different types available, as each offers unique advantages and caters to various production needs. The key categories of fabric printing machines include digital printing, screen printing, and dye sublimation. According to market research, the digital textile printing sector is expected to grow significantly, projected to reach $5.3 billion by 2023, largely due to its efficiency and versatility in handling short runs and complex designs.

Digital printing machines utilize inkjet technology, allowing for high-quality prints with vibrant colors and intricate details. This type is particularly advantageous for businesses that provide custom printing services. In contrast, screen printing remains popular for high-volume orders due to its cost-effectiveness and ability to produce large quantities of consistent prints. According to a report by Smithers Pira, screen printing comprised over 25% of the textile printing market share in 2021, indicating its continued relevance.

Dye sublimation stands out for its ability to print on synthetic fabrics, making it ideal for sportswear and fashion applications. This technique infuses dye directly into the fabric, resulting in durable, high-quality prints that resist fading and peeling. As more businesses aim for sustainable practices, dye sublimation's eco-friendly inks and processes are increasingly appealing. Understanding these types of fabric printing machines allows businesses to align their choices with their production goals and market demands effectively.

Top 10 Tips for Choosing the Right Fabric Printing Machine for Your Business

This bar chart illustrates the key factors to consider when selecting a fabric printing machine, based on their importance in business operations.

Assessing Your Business Needs and Production Volume

When selecting the right fabric printing machine, understanding your business needs and production volume is essential. According to a report by Smithers Pira, the global digital textile printing market is expected to reach $3.3 billion by 2025, partly driven by increased demand for custom and short-run printing. Businesses must evaluate their specific requirements, such as the types of fabrics they will be printing on, the desired print quality, and the range of designs they wish to produce. In recent years, there has been a notable shift towards sustainable practices in the textile industry, with research indicating that 60% of consumers prefer brands that use eco-friendly materials and processes. This growing trend underscores the importance of uptime and the efficiency of the chosen printing machine, as sustainable production often demands more sophisticated technology.

Moreover, assessing production volume plays a crucial role in this decision-making process. A study by Allied Market Research highlights that small to medium-sized businesses often struggle with scalability in production, which can lead to significant bottlenecks if the printing machines do not align with their output needs. For example, a facility with a projected output of 1,000 meters per week will require a different set of features and capabilities than one producing at a rate of 5,000 meters per week. Therefore, it's critical to analyze not only the current needs but also future growth potential, ensuring that the selected machine can handle increased volume without compromising quality or efficiency. This strategic foresight is vital to staying competitive in a rapidly evolving market.

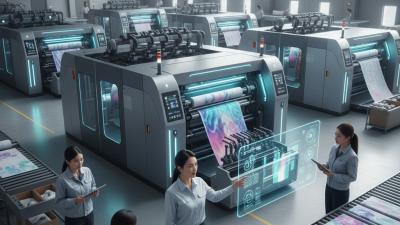

Key Features to Look for in Fabric Printing Machines

When selecting a fabric printing machine for your business, it’s essential to focus on key features that can significantly influence efficiency and output quality. One crucial aspect is the printing technology employed by the machine.

Digital textile printing has gained momentum, with reports indicating a projected CAGR of 16.6% in the digital textile printing market from 2021 to 2026. This shift towards digital solutions highlights the importance of investing in machines that offer high-speed printing, versatility in fabric types, and accessibility for small runs, catering to the evolving demands of custom printed textiles.

Another vital feature is the printer’s color accuracy and consistency. Machines equipped with advanced color management software can improve output quality, ensuring that the shades and hues match expectations across different batches. According to a recent survey by the Specialty Graphic Imaging Association, 77% of fabric printing businesses identified color fidelity as a crucial factor in customer satisfaction. Therefore, choosing a machine with reliable color profiles and robust calibration capabilities is indispensable in maintaining high standards in fabric printing.

Lastly, consider the maintenance and support services that come with the machine. The fabric printing industry is increasingly leaning towards sustainability, and machines that offer easy maintenance can significantly reduce downtime and operational costs. A report by Smithers Pira suggests that businesses prioritizing machine uptime can enhance their overall productivity by 20-30%. Thus, ensuring your selected fabric printing machine is not only high-quality in results but also user-friendly in terms of maintenance will ultimately benefit your operation in the competitive textile market.

Evaluating Cost and Budget Considerations

When selecting a fabric printing machine for your business, evaluating cost and budget considerations is crucial. Start by assessing the initial investment required for the machine itself, which can vary significantly based on the technology and features included. Consider whether to purchase a new or used machine, as used machines can offer substantial savings, but may come with hidden costs related to repairs and maintenance. Additionally, factor in the costs of peripherals, such as software and hardware upgrades, which can enhance the machine's capabilities.

Once the purchase price is determined, analyze the long-term operational costs associated with running the machine. This includes the cost of inks and materials, maintenance, and energy consumption. An efficient machine may have a higher upfront cost but could save money over time through reduced operational costs. It's also wise to account for potential downtime and how it might affect your production schedule and profitability. By carefully considering both the initial and ongoing costs, you can make an informed decision that aligns with your business's financial goals.

Top 10 Tips for Choosing the Right Fabric Printing Machine for Your Business - Evaluating Cost and Budget Considerations

| Tip Number | Tip | Cost Consideration | Expected ROI |

|---|---|---|---|

| 1 | Assess Your Printing Needs | Low | High |

| 2 | Evaluate Different Printing Technologies | Medium | Medium |

| 3 | Consider Operating Costs | High | Medium |

| 4 | Look for Versatility | Medium | High |

| 5 | Check Maintenance and Support | Low | High |

| 6 | Review User-Friendliness | Low | Medium |

| 7 | Compare Brands and Models | Medium | Medium |

| 8 | Evaluate Warranty and Guarantees | Low | High |

| 9 | Analyze Production Speed | Medium | High |

| 10 | Make an Informed Decision | Varied | High |

Researching Brands and Customer Reviews for Reliability

When selecting a fabric printing machine for your business, one of the crucial steps is researching brands and evaluating customer reviews for reliability. According to a recent industry report from MarketsandMarkets, the global textile printing market is projected to grow from $2.3 billion in 2020 to $4.9 billion by 2025, highlighting an increasing demand for quality fabric printers. This growth underscores the importance of choosing a machine that not only meets your technical needs but also has a solid reputation in the market.

Customer reviews and feedback offer invaluable insights into a machine's performance, durability, and overall satisfaction. Research published by IBISWorld indicates that 67% of consumers consider online reviews to be a decisive factor when making purchasing decisions. Therefore, it’s essential to aggregate user opinions across various platforms to gain a comprehensive understanding of each brand’s reliability. Not only should you look for high ratings, but also pay attention to the specific comments about customer service, maintenance issues, and the longevity of the machines in real-world settings. This qualitative data can significantly influence your investment decision and ensure you choose a fabric printing machine that aligns with your business goals.

Related Posts

-

Top 10 Fabric Printing Machines for High Quality Custom Designs

-

Top 7 Direct to Fabric Printing Machines Revolutionizing Textile Production

-

Top Benefits of Using Fabric Inspection Machines for Quality Control

-

What is a Fabric Weaving Machine and How Does it Work in Textile Production

-

2025 Top 10 Textile Printing Machines Revolutionizing the Industry

-

Exploring the Advantages of Modern Textile Cutting Machines in Fashion Industry Production