Top 10 Carding Machine Innovations You Should Know About?

In the rapidly evolving textile industry, innovations in carding machines play a crucial role. Experts like Dr. Emily Chen, a leading specialist in textile technology, emphasize this, stating, "Carding machines are the backbone of efficient fiber processing." Understanding this technology is essential for anyone interested in textile manufacturing.

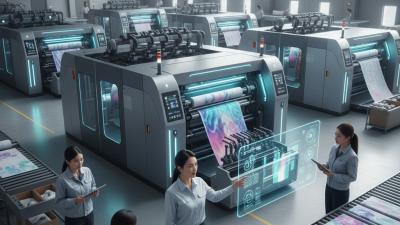

Recent advancements have transformed traditional carding machines into highly efficient tools. Many now feature smart technology and automation, improving precision and reducing waste. These features enhance productivity, making it possible to process fibers with greater speed and accuracy. However, there are still challenges in the industry. Not all innovations are widely adopted, and some manufacturers resist change.

There is a clear need for dialogue on modernization. It is vital for industry stakeholders to reflect on the balance between innovation and tradition. As we explore the top 10 carding machine innovations, we need to consider their potential impacts and the challenges they bring. Understanding these changes will shape the future of textile production.

Leading Innovations in Carding Machine Technologies

Carding machine technologies have rapidly evolved over the years. These innovations enhance efficiency and product quality. Modern carding machines are now equipped with advanced sensors. They monitor the fiber input and dust removal in real time.

One major innovation is automation. Automated settings reduce manual errors and increase precision. This also saves time during production. However, not all machines adapt to this technology easily. Some factories face challenges in retraining staff.

Tips: Regular maintenance of carding machines improves their lifespan. Additionally, check the calibration settings periodically. This ensures consistent fiber quality. Integrating emerging technologies can be daunting, but the benefits are significant. Embracing change is not just about investing in new machines; it also involves managing workflow effectively. Finding a balance is crucial.

Key Features of Modern Carding Machines Enhancing Efficiency

Modern carding machines are at the forefront of textile innovation. Their efficiency has seen significant advancements in recent years. Data from industry reports indicates that the global market for carding machines is projected to grow by 5.2% annually through 2026. This growth is fueled by technological enhancements that optimize production processes.

Key features of contemporary carding machines include automated settings and intelligent monitoring systems. These improvements allow for real-time adjustments, thereby reducing material waste. One study highlighted that machines equipped with advanced sensors can reduce downtime by 25%. This capability is vital for manufacturers aiming to maintain competitiveness in a fast-paced market.

Despite these advancements, challenges persist. Some manufacturers struggle to integrate new technologies due to high initial costs. Additionally, not all the existing workforce is trained to operate modern equipment. Ensuring staff adaptability is crucial for maximizing efficiency gains. Balancing innovation with practical implementation remains a continuous effort in the industry.

Top 10 Carding Machine Innovations You Should Know About

| Innovation | Key Features | Efficiency Improvements | Environmental Impact |

|---|---|---|---|

| Automatic Feed Systems | Real-time monitoring and adjustments | Increased throughput | Reduced waste generation |

| Smart Sensors | Predictive maintenance capabilities | Minimized downtime | Lower energy consumption |

| Energy-efficient Motors | High torque and low energy loss | Energy savings up to 30% | Reduction in carbon footprint |

| Modular Design | Customizable for various applications | Enhanced scalability | Optimized resource use |

| Advanced Processing Algorithms | Improved fiber alignment | Higher quality output | Less material wastage |

| Integrated Data Analytics | Real-time performance tracking | Data-driven decision making | Enhanced operational efficiency |

| Noise Reduction Technologies | Vibration dampening materials | Better working environment | Compliance with regulations |

| User-Friendly Interfaces | Touchscreen controls and analytics | Reduced training time | Improved operational safety |

| Remote Monitoring Capabilities | Access from anywhere | Enhanced responsiveness | Lower operational risks |

| Eco-friendly Materials | Biodegradable components | Sustainable production practices | Minimized waste impact |

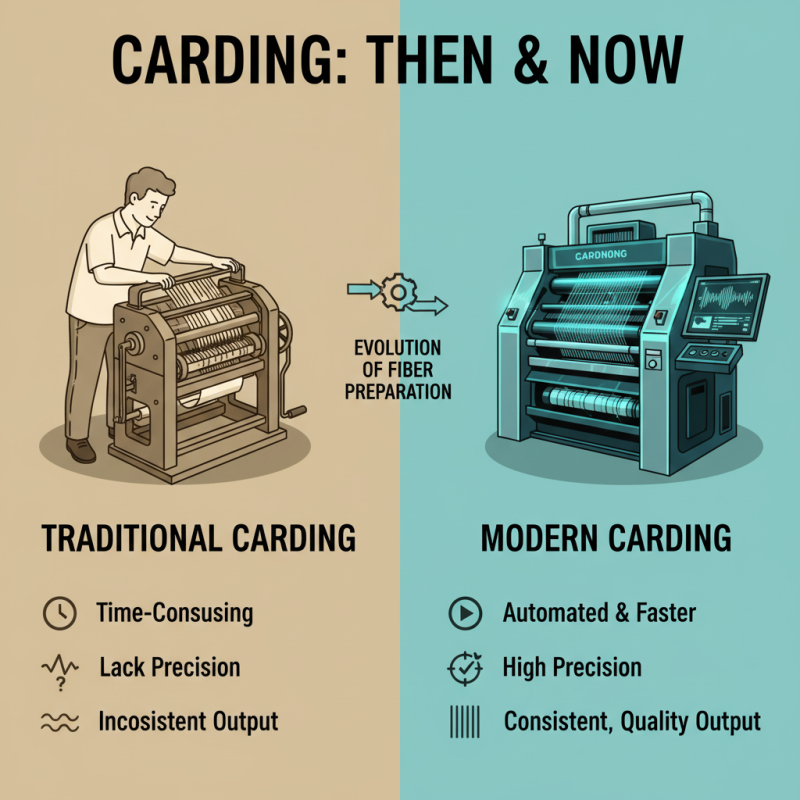

Comparative Analysis of Traditional vs. Innovative Carding Processes

The world of carding has evolved significantly with modern innovations. Traditional carding processes often rely on manual labor and simpler machinery. These methods can be time-consuming and lack precision, leading to inconsistencies in fiber preparation. Operators might find themselves struggling with the unevenness of carded materials. This can affect the quality of the final product.

In contrast, innovative carding machines use advanced technology to streamline the process. Automated functions improve the efficiency and uniformity of fiber separation. Smart sensors can monitor input quality, making real-time adjustments. However, these machines require significant investment and training. Some operators may feel overwhelmed by the complexity of new technology. This transition can lead to operational challenges, highlighting the importance of ongoing education in the textile industry. Balancing tradition and innovation is key for better outcomes.

Impact of Automation on Carding Machine Performance

Automation has significantly transformed the textile industry, particularly in carding machine performance. By integrating advanced technology, carding machines now operate with improved efficiency. Automated systems enhance productivity by reducing manual labor. This shift allows for quicker processing and consistent output quality. Real-time monitoring can detect issues early, minimizing downtime.

However, the transition to automation isn't flawless. While machines are faster, they sometimes lack the nuanced decisions that skilled operators make. Automation can lead to unexpected challenges. For example, some automated systems may misinterpret raw material quality. This can result in wasted resources and increased costs. Continuous evaluation and adjustments may be necessary to ensure optimal performance.

Balancing technology and human oversight is key. As machines assume more responsibilities, skilled workers must adapt. There are concerns about job displacement within the industry. Yet, this can lead to opportunities for upskilling. The future of carding machines lies in harnessing automation while still valuing human expertise. Finding that balance demands ongoing reflection and innovation.

Top 10 Carding Machine Innovations Impacting Performance

Sustainable Practices in the Development of Carding Machines

As the textile industry evolves, sustainable practices in carding machine development become crucial. Many innovations now focus on energy efficiency. For instance, machines that consume less electricity are rising in popularity. They use advanced sensors to regulate operations according to workload. This adjustment helps save energy and reduce costs, but are manufacturers fully embracing these technologies?

Environmental impact is another consideration. Carding machines now often utilize recycled materials in their components. This shift reduces waste in production. However, there's a need for more transparency in sourcing. Consumers are becoming more aware of where materials come from, and manufacturers must address this demand.

Tip: Regular maintenance can lengthen the lifespan of carding machines. Scheduled checks can prevent energy waste.

Sustainability also touches on water use. Innovative carding processes reduce water consumption. Machines designed with water-efficient systems help meet this goal. However, many facilities still rely on outdated technology, which may need re-evaluation. The industry must balance cost and sustainability challenges.

Tip: Investing in technology upgrades may seem costly but can pay off in the long run. Keeping up with advancements is vital.

Related Posts

-

Why Investing in Textile Machinery is Essential for Modern Manufacturing Success

-

Top 10 Fabric Printing Machines for High Quality Custom Designs

-

Top 10 Digital Textile Printing Machines to Enhance Your Printing Business

-

2025 Top 10 Textile Printing Machines Revolutionizing the Industry

-

2026 How to Operate an Ultrasonic Fabric Cutting Machine Effectively?

-

Top 10 Tips for Choosing the Right Fabric Printing Machine for Your Business