Top Fabric Coating Machines of 2025: Key Features and Buying Guide

As the textile industry continues to evolve, the demand for innovative solutions in fabric processing has prompted significant advancements in technology. One of the most essential tools in this domain is the fabric coating machine. These machines play a crucial role in enhancing the functionality and aesthetics of textiles by applying various coatings that improve durability, water resistance, and general performance. As we look ahead to 2025, understanding the key features of top fabric coating machines becomes vital for manufacturers aiming to stay competitive in the market.

When selecting a fabric coating machine, buyers must consider several critical factors that impact performance and efficiency. Features such as coating thickness control, speed, versatility in handling different materials, and ease of operation are paramount in ensuring that the investment meets production goals. Additionally, advancements in automation and digital controls are reshaping the capabilities of these machines, making it imperative for industry professionals to keep abreast of the latest technological developments.

In this article, we will explore the top fabric coating machines of 2025, providing insights into their essential features and offering a comprehensive buying guide to help stakeholders make informed decisions. Whether for large-scale production or niche applications, understanding the nuances of fabric coating machinery will empower textile manufacturers to enhance their product offerings while meeting the growing demands of the marketplace.

Overview of Fabric Coating Machines: Definition and Applications

Fabric coating machines play a vital role in the textile industry, offering an innovative solution for enhancing the functionality and performance of fabrics. Defined as machines that apply a layer of coating on textiles to impart desirable properties such as waterproofing, stain resistance, and flame retardancy, these machines contribute significantly to the production of specialized fabrics used in various applications.

According to a report by Research and Markets, the global fabric coating market is expected to grow from USD 5.4 billion in 2020 to USD 8.2 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.6%. This growth is largely driven by increasing demand from industries such as automotive, construction, and medical.

The versatility of fabric coating machines is showcased by their applications across diverse sectors. For instance, in the automotive industry, coated textiles are utilized for interior upholstery, enhancing durability and aesthetic appeal. In the medical field, these machines provide coated fabrics that are essential for creating disposable gowns and drapes that meet hygiene standards. Furthermore, advancements in coating technologies, including digital printing and lamination, have expanded the creative possibilities for textile manufacturers. With sustainability becoming a priority, many fabric coating machines now incorporate eco-friendly processes that minimize waste and reduce hazardous emissions, aligning with industry standards and environmental regulations.

Key Features to Consider When Choosing a Fabric Coating Machine

When selecting a fabric coating machine, various key features must be considered to ensure it meets both your production needs and quality standards. First, assess the machine’s coating method, as this determines the application and uniformity of the coating on the fabric. Common methods include spray, roll, and dip coating, each serving different purposes and offering varying levels of control over the process. Understanding the intended use of the coated fabric will guide the choice of the most suitable method.

Another crucial factor is the machine's throughput capacity. Depending on your production demands, you may require a machine that can handle high volumes efficiently. Look for specifications related to speed, productivity, and the ability to work with various fabric types and widths. Additionally, the machine's ease of operation and maintenance are essential. Features such as user-friendly interfaces, automated controls, and accessible maintenance points can significantly enhance operational efficiency and reduce downtime. Lastly, consider environmental factors, including the machine’s energy consumption and waste management capabilities, as these contribute to both operational costs and sustainability goals.

Top Fabric Coating Machines of 2025: Performance Comparison

Top Fabric Coating Machines of 2025: A Comparative Analysis

The fabric coating machines market is poised for significant growth in 2025, driven by advancements in technology and increasing demand across various sectors, including automotive, textiles, and medical applications. A recent industry report from Technavio estimates the global fabric coating market will grow by over 7% annually through 2025, highlighting the need for manufacturers to invest in innovative coating solutions. One of the key trends identified is the integration of automation and smart technology, which enhances efficiency and precision in the application process. These features allow for better control of coating thickness and uniformity, essential factors in producing high-quality coated fabrics.

In conducting a comparative analysis of the top fabric coating machines of 2025, several features stand out. Machines equipped with multi-functional capabilities, such as simultaneous coating and drying processes, are gaining popularity due to their time-saving benefits. Additionally, machines with environmental controls, such as closed-loop systems that minimize waste and VOC emissions, align with the industry's increasing shift towards sustainability. Companies are also focusing on ease of maintenance and digital interfaces, allowing operators to adjust settings and monitor performance remotely. This adaptability is crucial in meeting varying production requirements while maintaining high standards of quality and safety across applications.

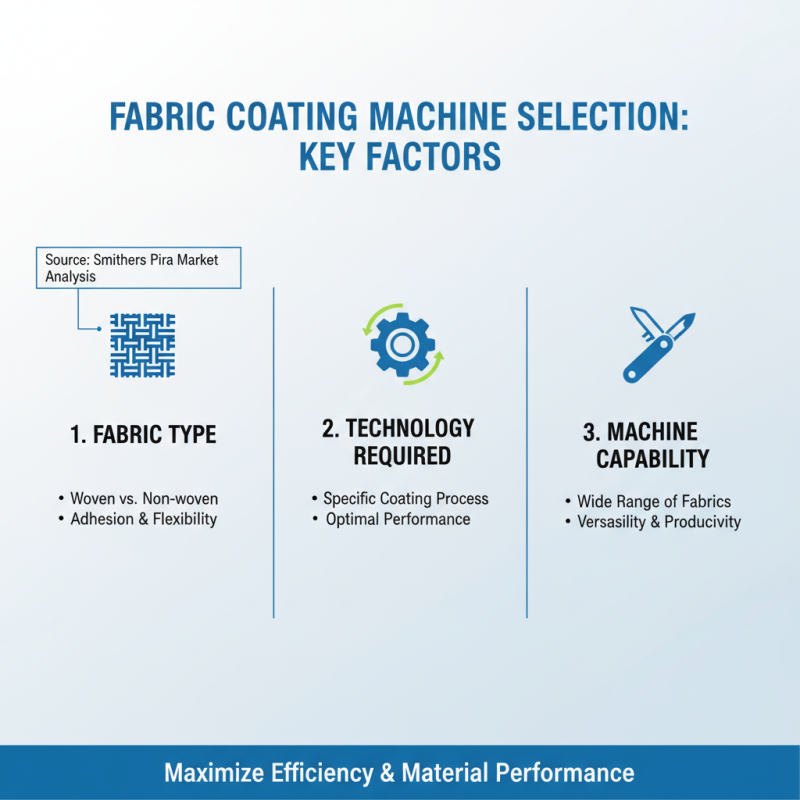

Buying Guide: Factors Influencing Your Fabric Coating Machine Choice

When selecting a fabric coating machine, several critical factors come into play that can significantly influence your decision. First, one must consider the type of fabric being coated. According to a market analysis by Smithers Pira, different fabrics require specific coating technologies to achieve optimal performance characteristics. For instance, woven fabrics may need a different treatment compared to non-woven materials, especially in terms of adhesion properties and flexibility. Moreover, the machine's capability to handle a wide range of fabrics can enhance versatility and productivity.

Another essential aspect is the machine's efficiency and output rate. The global fabric coating equipment market is projected to grow at a CAGR of around 6.5% through 2025, driven by increasing demand for high-performance textiles across various sectors. Buyers should evaluate machines based on their throughput rates and overall energy consumption. This not only impacts operating costs but also affects production downtime and maintenance schedules. Moreover, features such as automated controls and real-time monitoring can help streamline processes and reduce labor costs, making them crucial considerations for manufacturers aiming to improve overall production efficiency.

Future Trends in Fabric Coating Technology and Innovation

The fabric coating industry is poised for a significant transformation in the coming years, driven by advancements in technology and shifting consumer demands. According to a recent report from Grand View Research, the global fabric coating market is projected to reach USD 5.9 billion by 2025, growing at a compound annual growth rate (CAGR) of 4.6% from 2020 to 2025. This growth is attributed to the increasing need for performance textiles that offer durability, weather resistance, and enhanced aesthetic appeal. The integration of smart technologies into fabric coating processes—such as IoT-enabled machines—will likely enable manufacturers to monitor and optimize operations in real-time, improving efficiency and reducing waste.

In addition to technological advancements, sustainability is becoming a key focus within the fabric coating landscape. Reports indicate that eco-friendly materials and processes are gaining traction, with many manufacturers exploring water-based coatings and bio-based polymers as alternatives to conventional solvents. According to a recent study by Technavio, the adoption of sustainable practices in the fabric coating segment is expected to boost market growth by ensuring compliance with stringent environmental regulations and meeting consumers' increasing preference for environmentally friendly products. As the industry embraces innovation and sustainability, stakeholders must remain attuned to these emerging trends to stay competitive and meet the evolving needs of the market.

Top Fabric Coating Machines of 2025: Key Features and Buying Guide

| Model | Coating Technology | Max Width (cm) | Production Speed (m/min) | Energy Consumption (kWh) |

|---|---|---|---|---|

| Model A | Water-Based Coating | 200 | 15 | 5 |

| Model B | Solvent-Based Coating | 250 | 20 | 6 |

| Model C | UV Coating | 180 | 10 | 4 |

| Model D | Nano Coating | 150 | 25 | 7 |

| Model E | Electrostatic Coating | 300 | 30 | 8 |

Related Posts

-

Top 10 Fabric Printing Machines for High Quality Custom Designs

-

2025 Top 10 Textile Printing Machines Revolutionizing the Industry

-

Revolutionize Your Business with Advanced Industrial Fabric Printing Machines: Trends and Tips for Success

-

What is a Fabric Recycling Machine and How Does It Benefit the Environment

-

Top 5 Benefits of Using Industrial Fabric Laser Cutting Machines for Your Business

-

Top 10 Best Weaving Machines for Efficient Textile Production