Top 10 Tips for Using Ultrasonic Fabric Cutting Machines Effectively

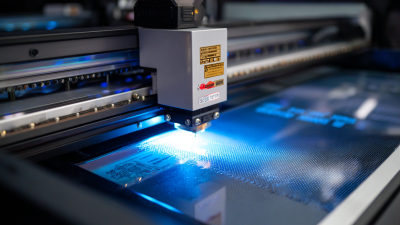

In the world of textile manufacturing, an ultrasonic fabric cutting machine is a game-changer. These machines offer precision and efficiency that traditional methods often lack. The ultrasonic technology allows for clean cuts, reducing fraying and improving overall quality.

However, using an ultrasonic fabric cutting machine effectively requires knowledge and practice. Operators sometimes overlook the importance of material type and thickness, which can impact cutting performance. Adjusting the machine settings for different fabrics is crucial. Careful attention can lead to better outcomes and reduce material waste.

Embracing the full potential of these machines means understanding both their strengths and weaknesses. While they enhance productivity, not every fabric behaves the same. Operators must adapt and refine their techniques for optimal results. Developing familiarity with the equipment ultimately leads to a more efficient production process.

Understanding the Basics of Ultrasonic Fabric Cutting Machines

Ultrasonic fabric cutting machines are revolutionizing the textile industry. These machines use high-frequency vibrations to create clean cuts. They minimize fraying, which is crucial for certain fabrics. Understanding how they work is the first step to effective usage. The technology relies on ultrasonic waves that heat the fabric edges. This process is efficient and precise, making it ideal for various applications.

To maximize your machine's effectiveness, keep the cutting area clean. Dust can affect performance, leading to uneven cuts. Regular maintenance is also vital. Check the ultrasonic converter to ensure it's functioning correctly. Silence in operation is a good sign. If it produces unusual noises, perform a check-up.

Consider the fabric type you're cutting. Different materials require different settings. Test cuts on scraps can help fine-tune the machine. It takes practice to master the settings, so patience is necessary. Keep a log of successful settings for future reference.

Mistakes are part of the learning process. Embracing them will improve your skills over time. A little trial and error can lead to great results.

Selecting the Right Machine for Your Fabric Cutting Needs

Selecting the right ultrasonic fabric cutting machine is crucial for efficiency. The right machine can enhance productivity and reduce waste. When considering your options, focus on the type of fabric you work with. A specialized machine may yield better results for thicker materials compared to a general one.

Data indicates that ultrasonic cutters can improve cutting speed by up to 40%. However, choosing a machine that isn’t suitable for your fabric type can lead to subpar outcomes. For instance, delicate fabrics might fray if the cutter’s power is too high. There’s a fine balance between performance and adaptability.

Investing time in understanding different models is essential. Reading user reviews and technical specifications can provide insight into machine performance. Some users report initial challenges with calibration, which led to inconsistent cuts. It’s important to be prepared for a learning curve when operating new machinery. Proper selection will save time and materials in the long run.

Top 10 Tips for Using Ultrasonic Fabric Cutting Machines Effectively

Preparing Fabrics for Optimal Ultrasonic Cutting Performance

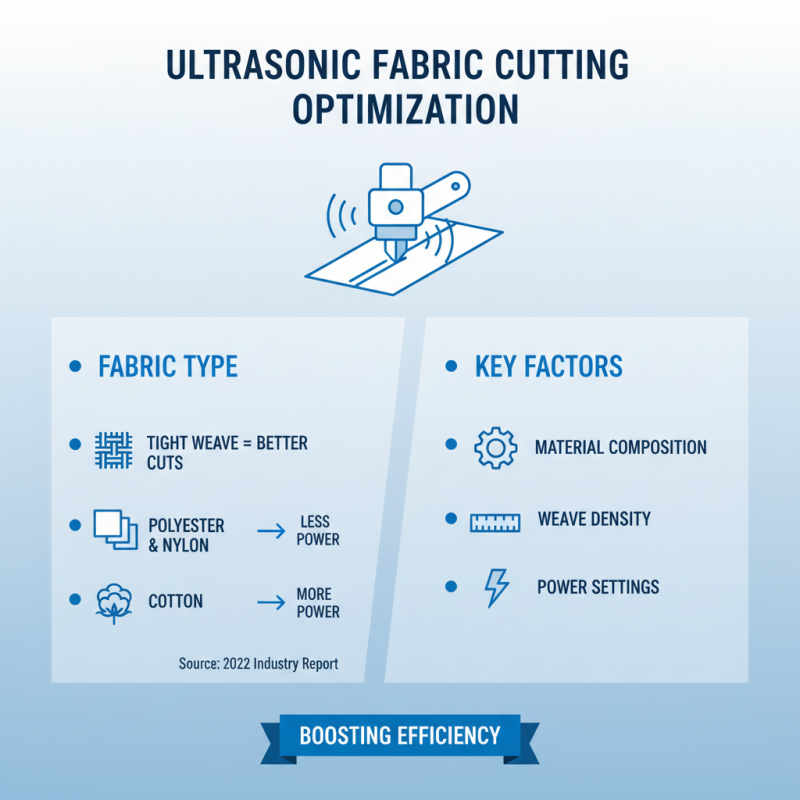

Preparing fabrics for optimal ultrasonic cutting performance involves several key factors. First, the type of fabric plays a crucial role. Fabrics with a tight weave tend to yield better cutting results. According to a 2022 industry report, fabrics like polyester and nylon require less ultrasonic power compared to cotton. Understanding this can enhance the cutting efficiency considerably.

Prior to cutting, ensure that fabrics are clean and free from contaminants. Dust or oils can obstruct the cutting process. A clean surface allows for more precise cuts. It's also advisable to trim excess material, as this minimizes wasted fabric and enhances machine performance. Reports indicate that up to 15% more fabric can be utilized when preparing it properly.

Thickness matters, too. Using a gauge to measure the fabric's thickness can provide valuable insights. Ultrasonic machines can struggle with thick materials. Also, experimenting with different frequencies can yield varying results. Some users report that trial and error is often necessary. Embracing these imperfections in the process helps refine techniques for better outcomes.

Techniques to Maintain and Troubleshoot Ultrasonic Cutting Machines

When it comes to ultrasonic cutting machines, proper maintenance is crucial. Regular cleaning can prevent buildup and improve performance. Industry reports indicate that nearly 30% of downtime in textile manufacturing is due to equipment malfunction. This highlights the importance of routine checks. Inspect the ultrasonic stack regularly. Ensure components are free of debris.

Troubleshooting issues promptly can save time and money. If you notice inconsistent cutting, it may be time to recalibrate the machine. Many operators overlook this step. It’s common to see irregular cuts become more frequent as machines age. Industry studies show a direct correlation between machine maintenance and product quality. For instance, improper maintenance can increase defect rates by up to 25%.

Additionally, training operators is vital. Educated users can identify problems before they escalate. Issues could include incorrect settings or worn-out components. Take time to review operating manuals and safety protocols. Operators who lack experience contribute to many common failures. Investing in proper training can reduce repair costs significantly. Regular feedback sessions can help enhance problem-solving skills.

Tips for Enhancing Efficiency and Safety During Operation

Using ultrasonic fabric cutting machines requires attention to efficiency and safety. Maintain a clean workspace to avoid accidents. A cluttered area can lead to mistakes, causing delays and injuries. Regularly inspect the machine for potential issues. Small problems can escalate quickly if ignored.

Proper training for operators is essential. Each team member should understand the machine's operations. This minimizes risks of misuse. Even experienced operators may forget basic protocol. Encouraging regular safety drills can keep everyone sharp. Creating a checklist for safe operation is also a good practice.

Regular maintenance is non-negotiable. Ensure all parts function correctly to avoid downtime. If a machine starts to malfunction, address it immediately. Decisions made in haste can lead to larger complications. Documenting repairs helps track patterns that could signal deeper issues. These practices foster a culture of safety and efficiency.

Top 10 Tips for Using Ultrasonic Fabric Cutting Machines Effectively

| Tip Number | Tip Description | Benefits |

|---|---|---|

| 1 | Regular Maintenance | Ensures optimal performance and longevity of the machine. |

| 2 | Correct Settings | Adjusting frequency and amplitude enhances cutting precision. |

| 3 | Proper Training | Reduces accidents and ensures safe machine operation. |

| 4 | Use of Protective Gear | Minimizes the risk of injuries during operation. |

| 5 | Material Compatibility | Using compatible fabrics ensures better cutting results. |

| 6 | Routine Calibration | Maintains accuracy for precise cutting dimensions. |

| 7 | Monitor Power Consumption | Helps in identifying machine inefficiencies early. |

| 8 | Keep Work Area Clean | Ensures safety and prevents operational hazards. |

| 9 | Documentation of Procedures | Improves efficiency through standard operating procedures. |

| 10 | Feedback System | Encourages continuous improvement based on user experience. |

Related Posts

-

Top 5 Fabric Weaving Machines: Revolutionize Your Textile Production Today!

-

How to Choose the Best Fabric Laser Cutting Machine for Your Business

-

How to Choose the Best Fabric Laser Cutting Machine in 2025

-

Top 5 Benefits of Using Industrial Fabric Laser Cutting Machines for Your Business

-

Why You Need a Carding Machine for Your Textile Production Efficiency

-

Top 10 Best Weaving Machines for Efficient Textile Production